Efficient bulk material logistics with sensor-based OWL EYE® material inventory tracking and digital VAS® yard management

The combination of sensor-based material tracking with OWL EYE® from Sachtleben Technology and the digital yard management solution VAS® from Axians IAS leads to greater transparency, efficiency, and automation in bulk material logistics. The integration of both systems provides accurate real-time data on material inventories, eliminating the need for manual reconciliation and optimizing delivery processes through the automation of logistics workflows.

The challenge: Inaccurate or non-integrated material inventory information

In the building materials industry, efficiency in plant logistics is a decisive competitive factor. Precise material flows, transparent inventory levels, and smooth loading processes are essential, especially in bulk material plants such as gravel, sand, or mixing plants. However, manual processes, inaccurate inventory data, and inefficient workflows still dominate in many places.

Another weak point is isolated applications, meaning that information on material stocks, if it is digitized at all, is often not available in a plant logistics solution or has to be entered manually into these systems. These challenges apply to many use cases in bulk material logistics. This article takes a closer look at the use case of material inventory recording and flow measurement and describes integrated, digital solutions.

The goal is to reduce waiting times and high manual coordination efforts in the delivery workflow, enable precise, automated control of loading processes, and avoid unnecessary transfers or production orders for restocking. Digitized material stocks and material flows thus transform just-in-case production into just-in-time production.

The solution: integration of digital plant logistics

and sensor-based material inventory tracking

The example of the integration of the OWL EYE® solution from Sachtleben Technology with VAS® plant logistics from Axians IAS illustrates how the disadvantages of isolated applications described in the last paragraph can be avoided and an efficient material logistics workflow achieved.

OWL EYE®: Full transparency of material stocks in bulk material plants

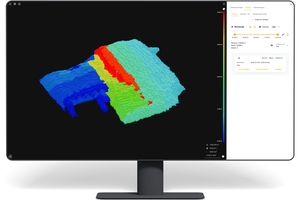

Sachtleben Technology specializes in sensor-based measurement technology for industrial bulk material processes. With the OWL EYE® system, the company offers a precise, automated solution for measuring the volume of stockpiles and material flow on conveyor belts. The technology is based on LiDAR sensors that continuously and in real time record material quantities in two and three dimensions – either stationary or mobile, for example on wheel loaders.

The LiDAR sensors provide the data basis that enables the intelligent software solution to determine precise material inventory information. The 3D data, presented in a user-friendly dashboard, allows even a layperson to perform accurate analyses of which material batch was stored at what time and in which area of a stockpile. As an alternative or supplement to material recording with permanently installed LiDAR sensors, this system can also be used in a mobile manner, e. g., by mounting sensors on a wheel loader to measure stockpiles as it drives by, thereby determining the material volume.

VAS® Yard Management from Axians IAS: The digitized

and automated delivery workflow in bulk material plants

Axians IAS, a VINCI Energies company, is an expert in digital plant logistics solutions. With VAS® Yard Management, Axians offers a modular platform for controlling the entire delivery process at the plant – from truck entry and loading to delivery note creation. The solution is already in use in numerous plants and is known for its high adaptability and depth of integration. Especially in plants with a high number of deliveries, it is extremely important to relieve the burden on plant personnel and to accelerate and simplify logistics processes, e.g., through self-service terminals for truck drivers at entry and exit points. In addition to many other applications, digitized support for loading processes is also available through solutions such as wheel loader terminals, optionally with connection to wheel loader scales.

Integration: Sensor technology meets smart logistics control

Automatic material recording and smart control of the delivery workflow have clear points of intersection. Precise real-time data determined with the help of OWL EYE® can be retrieved directly from the VAS® Yard Management System via an API. There, it serves as the basis for automated decisions and processes.

This is a clear motivation for both companies to enter into a partnership to jointly optimize logistics processes in bulk material plants. The advantages of this partnership between Sachtleben Technology and Axians IAS through the integration of their solutions are described using two specific use cases.

Stockpile measurement and loading point control

This application involves the automated measurement of bulk material stockpiles. Several LiDAR sensors from the OWL EYE® system continuously record the volume of the storage areas. The data collected is retrieved in real time by VAS® Yard Management.

There, rule-based actions can be triggered – such as the automatic selection of the optimal loading point for a delivery. This ensures that the most suitable resource is always used – e. g., the one with the highest or lowest fill level, depending on the desired logic, which can be freely configured in VAS®. The result: a faster check-in process and thus shorter throughput times for truck drivers, as well as optimized inventory management for the various storage and loading points.

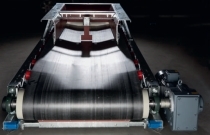

Controlling truck loading via conveyor belt

Another possible application scenario for this integration is the precise control of truck loading via conveyor belts. A sensor from the OWL EYE® system on the conveyor belt continuously measures the material flow. As soon as the target quantity defined in the delivery note is reached, the conveyor belt is automatically stopped – without manual intervention.

The result: precise loading, no overloading or underloading – even if there is no belt scale or it cannot be connected online. This leads to a significant reduction in material losses and a noticeable reduction in the workload for operating personnel.

Practical advantages of integration

The combination of OWL EYE® and VAS® Yard Management offers a number of advantages for operators of bulk material plants:

Real-time transparency:

Material stocks can be accessed at any time – both in stockpiles and at loading points.

Decisions (e. g., fill level-controlled loading point selection) are based on reliable data rather than estimates or experience.

Increased efficiency through automation:

Automatic selection of the optimal loading point reduces waiting times and minimizes empty runs.

Loading is faster and more precise – with less personnel required.

Production orders and transfers can be triggered in a targeted manner when stock levels fall below defined thresholds.

Sustainability and resource conservation:

Fewer transfers and empty runs mean lower emissions.

Precise load control reduces material losses.

Process digitalization saves paper, time, and energy.

Seamless integration into existing processes:

The systems are modular in design and can be flexibly connected to existing IT and logistics structures.

Fast and smooth implementation of integration via an existing API.

Individual rules and configurations allow for tailor-made adaptation to the respective plant requirements.

A look into the future: scalability and new fields

of application

The integrated solution is not only interesting for large plants. Small and medium-sized companies also benefit from the scalability of the systems. Initial projects are already running successfully at leading building materials manufacturers. In addition, new potential fields of application are opening up, such as:

Just-in-time loading based on real-time data

Automated production planning in the event of impending material shortages

Dashboards and KPIs for management to improve control of plant logistics

Conclusion: Digitalization with measurable added value

The combination of precise sensor technology and intelligent logistics control is a good example of successful digitalization in the building materials industry when companies contribute their expertise in various areas to an integrated solution. It shows how consistent data flows, automation, and real-time transparency not only increase efficiency but also contribute to sustainability and competitiveness.

For companies in the bulk materials industry, this integrated solution from partners Sachtleben Technology and Axians IAS is a future-proof building block on the road to the smart factory – practical, scalable, and with a clear ROI.

Authors:

Quirin Kraus1, Fynn Reuver1 und Reiner Bachthaler2

1 Sachtleben Technology, Bad Lauterberg im Harz/Deutschland

2 Axians Industrial Applications & Services, Ulm/Deutschland