Basis of utilization and development of technologies and machinery (Part 2.2)

Summary: The geological properties of the bituminous coal deposit of the Ruhr area are presented as an example of the characterization of a complex structured deposit. The properties are determined by sedimentary bedded rocks and differently coalified coal seams as well as elements of the constricted tectonics (saddles, synclines, folds, overthrusts) and the extending fracture tectonics (grabens, horsts, faults). The coal seams with their different geometrical and material properties (depths, dimensions of sectional coal beds, dippings, lithotypes) required continuous development of mining technology and machinery in the past in order to justify coal mining supported by subsidies. There are still significant coal reserves left despite a 700 year mining history and a closing of all mines in October 2018. However, the reserves are marginal on a global level. These strategic reserves for Germany can only be economically used in the future if new technologies will be developed.

4.1.2 Features

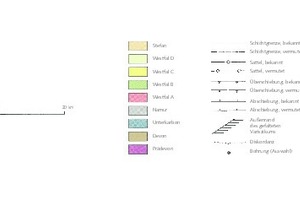

The hard-coal deposits of the Ruhr area are thus dominated by layers of sedimentary rocks and hard-coal seams, and also by elements of constricted tectonics and extending fracture tectonics. They principally comprise a folded structure attenuating in a north-westerly direction, consisting of anticlines and synclines running south-west to north-east, the vertical levels of which are controlled by their axis corrugation, distorting folds and accompanying overthrusts and, more or less perpendicular to these, grabens and horsts striking from south-east to north-west, with their causal faults (Fig. 19).

We thus have, in detail, deposits, the characterisation of which by means of geological features must take into account the complex fold and fracture tectonics, and also the differing stratum thicknesses (Fig. 20). The deposits are, in addition, subdivided into macroblocks and blocks by tectonic elements (discontinuities and dislocations) which form the boundaries. The strata included in a block can then be designated in terms of geometry and material [6, 21] (Fig. 21). A complex deposit, such as that of the Ruhr region, can now be characterized on this basis as shown in Figure 4 of the first part of this treatise [47]. Only the features of the coal seams are discussed below, although the features of the country rocks are also of importance, particularly for mining and coal-winning (e.g. heading of roadways, stability of mine workings).

4.1.2.1 Location

The Variscan Foreland with its practically continuously coal-bearing Upper Carboniferous strata extends across virtually the entire northern part of Germany and the territory of the Netherlands and then under the North and the Baltic seas (Fig. 1). The strata dip toward the north, i.e. the further north the coal seams are encountered, the deeper they are. This dip below the increasingly thick overburden is interrupted by local tectonic structures, as at the Osning Fault, at the Ibbenbüren Horst or at the Ochtrup Anticline, for example. The Ruhr‘s hard-coal deposits are thus only a small portion of the total coal reserves of the Variscan foreland.

4.1.2.1.1 Coordinates

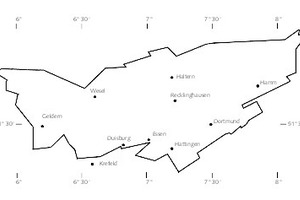

The deposits are bounded in the south by the outcrop of the seams. Here, the outcropping productive Upper Carboniferous was exploited by means of tunnels and sinkholes as early as the Middle Ages. The 1200 m basal contour line of the boundary between the Upper Carboniferous strata and those of the overburden may serve, at random, if also on a technological and economic basis, for delineation of the area under examination in the other directions in this treatise. Within these limits, the hard-coal-bearing strata extend more than 100 km in an east-to-west direction (from around 6 ° to 8 ° east of Greenwich) with a north-to-south dimension of around 50 km (± 51 ° 30‘ north of the Equator) (Fig. 22). An area of some 5621 km² is thus covered in total.

4.1.2.1.2 Depth

Coal-bearing strata of differing thicknesses at differing depths can be found in the area with the top contour of the Carboniferous located higher than 1200 m below the Earth‘s surface [7, 11, 22, 23] (Fig. 23). Seams located at a depth of between 1300 m and 1400 m account for the major part of the coal reserves; these are strata which have scarcely been mined at all. Higher seams have indeed been exploited up to the present day, but even these depth ranges still contain not inconsiderable reserves. Seams located below 1400 m remain entirely undisturbed. At all depths, the coal is present in seams of a thickness of less than one metre, although thicker seams do account for around one third of the reserves.

4.1.2.1.3 Orientation

The orientation of these seams can be stated in terms of their angle of dip and of strike. Angle of dip is critical for recovery of coal, with the result that seam inclinations are subdivided, for technological reasons, into dip groups. Classification of angle of dip is not uniform, however. One classification, for example, defines a low inclination of the seams as a dip of up to 20 gon, a moderately dipping seam with an angle of dip of 45 gon and steep deposits with an inclination of more than 45 gon [21]. Other classifications categorize low inclined deposits as from 0 to 20 gon inclination to the horizontal, moderately dipping as from over 20 to 40 gon, severely dipping as from more than 40 to 60 gon and then steep dip as from above 60 to 100 gon (equivalent to 90 °) [3].

Tectonic processes following the deposition of the coal-bearing strata resulted in differing dipping of the originally horizontal seams (Fig. 24). In view of the last happened limitation of mining to seams of low inclination, the recovery of hard coal is thus restricted to the higher zones of the anticline and the bottom of the syncline and left the sides and folded zones largely untouched. Such a restricted scope of mining resulted correspondingly in inadequate exploitation of the deposits [6].

4.1.2.2 Geometry

The geometry of strata is determined by the dimensions in three directions. Due to the seam-shaped configuration of the coal-bearing strata, the interfaces with the country rock in the floor and in the roof largely run in parallel, with the result their seam thickness remains approximately constant across large distances. The seams exhibit flexing in the vicinity of anticlines and synclines, as a result of folding, and elevated dips in the vicinity of the sides. As a result of faulting, a seam is, in addition, subdivided into individual sectors, which, in some cases, exhibit significant offsets to each other.

The seams of the Ruhr region occur in strata ranging from a few millimetres to several metres in thickness. Seam thicknesses greater than 4 m are rare, however. A seam of around 6.3 m was once encountered at the “Sachsen” mine, for example, but consisted in fact of several individual seams separated by thin bands [26].

Not all of the more than two hundred seams in the Ruhr area were economically exploitable. Exploitability depended on market situation, the available mining technology and the prevailing geological conditions. These interdependences also changed with time. The average thickness of coal seams mined in the 1930s was around 1.15 m pure coal, or around 1.25 m coal when the included and co-extracted mineral matter is included, but then rose to 1.25 m/1.41 m by 1960, and reached 1.42 m and 1.74 m in 1990 [6, 26, 28].

The continuity of the strata is also disrupted by fracture tectonics, with the result that faults divide the seams into part-seams and thus restrict their lateral extent. The tectonics of the hard-coal formation thus restricts the part-seams of constant stratum thicknesses. The intensity of the fracture tectonics varies greatly, however (Fig. 25). The number of faults and lateral faults per unit of length increases from south-east to north-west and thus behaves inversely proportionally to the confinement of the Ruhr Carboniferous, i.e., the more greatly the rock formation is folded, the fewer the transverse and diagonal faults that occur. In addition the large trench zones and main synclines tend to exhibit an elevated level of fracture tectonics, unlike the zones of axial depressions and main anticlines. Part-seams undisturbed for several 1000 m of their length and width as well as of a thickness of at least 1 m tend to be a rarity [9].

4.1.2.3 Materials2

The hard coals of the Ruhr area played a decisive role in the industrialisation of Germany. Not only the magnitude of the deposits, but also the various ranks of coal, in other words, the material features, were decisive. Some ranks were suitable to meet energy requirements in the form of steam coal for power-generating plants, town gas for private and industrial use and briquettes for domestic heating, while others supplied carbon as a metallurgical reductant, in the form of coke, for the iron and steel industry, and others, for their part, were used in coal chemistry for the production of basic chemical feedstocks, such as crude benzole and ammonia.

A parallel development occurred in coal analysis, for the determination of the geological, chemical and physical properties of coals. Coal, due to the differing input materials and geological conditions of its formation, is an extremely complex material resource, with the result that it cannot, even now, be characterized adequately from a purely scientific viewpoint. For this reason, additional material tests which supply technological characteristics (i.e. grindability, wear index) are performed, depending on the processes and machinery used or intended for use. Another complicating factor is that differing test methods and parameters have developed and are used in the “traditional” coal countries, such as Germany, Great Britain, Poland, France or the USA (e.g. USA: ASTM D 388; Australia: AS K 184; Poland: PN-68 / G-97 002). These problems remain apparent even today in the parallel validity of national standards which may, for example, complicate the export of machinery. There are, nonetheless, efforts at the development and definition of globally uniform criteria for characterization of the visibly and increasingly internationally traded commodity of coal, so-called “world coal” (e.g. DIN 23 003, which itself is no longer valid). It is, for these reasons, not possible to rigorously derive and compile coal‘s material features on a scientific basis.

This treatise will be restricted below to geological characterization of coal. The constituents and their configuration are the sources of coal‘s chemical, physical and technological properties. The constituents of coal comprise macerals, minerals and voids, while their configuration constitutes the structure of the coal. Coal, like rocks, can thus be geologically characterized by its constituents and their geometrical characteristics (e.g. dimensions and shape) and by their spatial arrangement (e.g. isometric, linear structure) [46].

Such geological characterization is based on extremely diverse methods, however. Not only geological, biological, chemical and physical analyses and terms are used, but also technological criteria which have been developed in the course of long years of practical mining of hard coal. The scientific derivation of the geological system for coals is therefore also not satisfactory, but is the result of historical development.

Characterization is also a function of scale. In mining, the geological formation plays the decisive role, whereas the seam is definitive for coal winning, and the lumps extracted from the seam are definitive for the processing plant. For this reason, geological characterization of coal is accomplished macroscopically by means of lithotypes, which cover a dimensional range extending from millimetres up to metres, and microscopically by means of microlithotypes, covering a range from micro- to millimetres, and by maceral groups and their macerals, and also by their parageneses. The proportions of the corresponding features are therefore also scale-dependent. A centimetre-large piece of the macroscopic lithotype fusain, which consists entirely of the fuselite maceral, exhibits a specific gravity of 0.215 to 0.4 kg/dm³, whereas pulverised fuselite exhibits figures of 1.38 to 1.46 kg/dm³. The reason can be found in the natural porosity of fusain [44].

In view of the complications described above, coals are characterized below on the basis of various criteria. The features derived from this result in various classifications of coals and of their constituents [1, 2, 4, 19, 20, 24, 26, 27, 41, 44, 54].

4.1.2.3.1 Coal2

The chemical substance groups and their reactivities, and also the material of origin, serve to delineate coal from other rocks. Coal consists correspondingly of a mixture of various inorganic and organic constituents, which are primarily of vegetable origin. Of these, the organic, and some of the inorganic substances (e.g. sulphur) are combustible. The inorganic, non-combustible components (e.g. quartz, calcite) generate ash during the combustion process. In geological terms, coal is, therefore, a combustible sedimentary rock of primarily vegetable origin, a “caustobiolite”.

The volumetric percentage of inorganic constituents is used for classification of coal as a rock (Fig. 26). Up to a content of 8 Vol-%, we have coal, and above this up to 20 Vol-%, impure coal. Above an inorganics content of 20 Vol-%, the rock is classified as carbonaceous shale, and at above 60 Vol-% as gangue [2].

4.1.2.3.2 Coal types2

Externally, coals can be differentiated into banded and non-banded coals. The cause of the differing external appearance of these two types of coal can be found in their origin.

Both types of coal indeed originate primarily from the continuous deposition of ever newly dying plants, which are biochemically converted in swamps. In the case of banded coal, the vegetable substance peatified on the surface of the Earth in swamps under severely obstructed access of oxygen due to the high groundwater level, whereas, in the case of the non-banded coals, the vegetable matter decomposes with the partial inclusion of animal substance below the surface of the water and with no exposure to oxygen. In both types, subsequent coalification takes place at great depths in the earth in diagenesis as a result of geobiochemical processes. Due to the differing intermediate substances occurring in genesis, the banded coals are also referred to as “humic coals” and the non-banded coals as “sapropelic coals”.

4.1.2.3.3 Coal ranks2

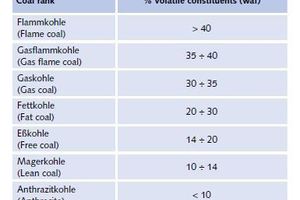

Various reactions generate from the initial vegetable substance a range of intermediate substances, which are converted by pressure and temperature to hard coals. This process is also known as “coalification”. The percentage contents of volatile constituents and hygroscopic water decrease as coalification progresses, while the carbon contents increase. The occurrence of hard coals of greatly differing coalification in individual strata in the Ruhr area resulted in a classification of the coal ranks on the basis of volatile-constituent contents (basis: water and ash free [waf]) (Fig. 27). Anthracites are practically totally coalified and degassed, whereas flame coals consist almost 50 % of volatile constituents.

4.1.2.3.4 Lithotypes2

Lumps or strips of coal which exhibit a uniform external appearance can now be separated out of the seams. These are used for macroscopic characterization. In the case of the humic coals, the visual impression is used for designation. The mining terms “bright”, “semibright”, “dull” and “fibrous” coal are adopted for this purpose. The internationally used names are based, in some cases, on other properties of the lithotypes, however. “Bright” coal, also known as vitrain, is black and exhibits a glassy lustre. Anthracite is this coal‘s purest form.

Unlike “bright” coal, “dull” coal generally has a grey undertone and exhibits a matt to dull lustre. The international term “durain” refers to another property of this coal, namely its hardness, however. “Semibright” coal occupies in visual terms an intermediate position between “bright” coal and “dull” coal. Its technical designation “clarain”, refers to the sound generated when the coal is struck.

“Fibrous” coal is grey to black, and has a silky, velvety lustre, and exhibits a fibrous appearance. These coals are also known as “fusain”, due to their highly colorative property.

Systematic analysis of the coals of the Ruhr area indicates a correlation between the coal ranks and the amounts of the individual lithotypes which they contain [27]. Here, fifty-eight seams from fifteen mines were sampled in a defined program (channel samples), the coal ranks being classified for these analyses into gasflame coal, gas coal, fat coal and lean coal and the lithotypes into “bright”, “dull”, “fibrous” coal and gangue(Fig. 28). The “fibrous” coal content varies only little between the individual coal ranks. The average in the Ruhr coal seams is 3.3 %. The “bright” and “dull” coal contents exhibit a contrary tendency. “Bright” coal contents in the gasflame coal and gas coal are around 65 % and increase to above 80 % in the fat and lean coal. The “dull” coal contents of gasflame coal and gas coal correspondingly decrease from 25 % to 13 % and to 7 % in the case of fat and lean coal. The jump in coalification between the gas coal and fat coal can be clearly recognised by the “bright” and “dull” coal contents [27]. The gangue contents are between around 3 and 6 % on average. Higher contents – frequently above 50 % in ROM coal – occur if it was not possible to keep out gangue during winning or when gangue from the roof and the floor entered the coal.

The lithotypes of sapropelic coals include cannel coal and boghead coal. Both coals have a black-brown, matt appearance, and are similar to the “dull” coal. Their names derive from their combustion properties and the place at which they were first described. In small fragments, cannel coal can be easily ignited and then burns like a candle. The designation “boghead coal” comes from the Scottish town of Boghead.

The quantities of cannel coal and boghead coal in the Ruhr region are of no importance. They nonetheless constitute not insignificant reserves locally, however. Cannel coal is found in seams and seam groups of between a few centimetres and 1.4 m and in horizontal extents of a few 100 m and several kilometres, as in the case of Seam 12 at the Schlägel und Eisen 5/6 colliery and in the Zollverein 6 seam at the Helene-Amalia Colliery (Helene Shaft). Boghead coals occur more rarely. They are found in seam groups, as in Seam Z at Auguste Victoria Colliery and in Seam 2 at the Friedrich Thyssen II/V Colliery. Mixed types consisting of cannel and boghead coals also occur, at the Lohberg Colliery, for example [26].

4.1.2.3.5 Microlithotypes2

The lithotypes examined macroscopically are composed at the microscopic level of microlithotypes with differing maceral paragenesis and mineral paragenesis in each case. The microlithotype represents the intergrowth of the maceral groups, with minerals contents ranging up to 60 % (on this, see Sections 4.1.2.3.6 and 4.1.2.3.8). Where minerals content is low (< 8 Vol-%), with the result that the density of the hard coal does not exceed a figure of 1.5 g/cm³, the microlithotype is designated on the basis of its maceral composition [20]. Three microlithotypes are differentiated in this context, namely vitrite, liptite and inertite, which can occur in isolation and also in combinations of two and three of these types (Fig. 29). The combinations of two types are assigned separate designations, as in the case of clarite, the combination of vitrite and liptite, of durite, consisting of liptite and inertite, and of vitrinertite, consisting of vitrite and inertite. The nomenclature of the tri-maceral microlithotypes is orientated around the prevailing percentages of the maceral groups making them up. Where the vitrinite contents dominate, with subordinate amounts of inertinite, we have duroclarite, and with the reverse proportions clarodurite [1, 24]. Where, on the other hand, inertite dominates above vitrite and liptite, the term “vitrinertoliptite” is used.

Microlithotypes with an elevated minerals content (8 ÷60 Vol-%) increase the density of the hard coal. Where this is between 1.5 to 2.0 g/cm³, these microlithotypes are referred to as carbominerites. The designation of the coal/mineral intergrowth is then accomplished as a function of the included minerals and on the basis of the predominant mineral group, although this is not rigorous, scientifically speaking, since differing percentages of other minerals are permitted. Not only these primarily mono-mineral coal/mineral intergrowths with a dominant percentage of one mineral group but also intergrowths including several mineral groups, occur. These poly-mineral intergrowths are known as carbopolyminerites [20] (Fig. 29). These minerals are referred to as gangue if the minerals content exceeds 60 Vol-% or the density of the coal 2.0 g/cm³ (Fig. 26).

Macerals and minerals are more or less intimately intergrown with one another, depending on their genesis. Here, the syngenetic and epigenetic inorganic constituents are counted as mineral inclusions [19]. Other minerals (including oxide ores and sulphates, for example) may also be present as inclusions, however, without any special names applying here. The term “salt coal” is used when salts are included, on the other hand.

4.1.2.3.6 Maceral groups2

Coals are not homogenous, but consist, instead, of various structural constituents, the “macerals”, which are collated into “maceral groups” depending on their initial substance and their conversion during the coalification process. The subdivision of the maceral groups is based on the three components of the vegetable substrate. The humous constituents consist primarily of protein, cellulose, lignin and tannoids, which form the macerals of the vitrinite group in the course of the coalification process. The fat components comprise, primarily, resins, waxes, fats, oils, latex and cork, the coalification products of which are assigned to the exinite macerals group. The third group, the inertites, are the result of the conversion of the inert constituents of the plants, such as chitin and charcoal-like components.

The various coal types and lithotypes, and also the microlithotypes, consist of individual maceral groups (Fig. 30). Some coals, such as “bright” coal, consist predominantly of only one maceral group, namely more than 95 % of vitrinite, whereas “semibright” coal is formed from not less than two maceral groups of differing compositions.

4.1.2.3.7 Macerals

The macerals are the smallest organic constituents of coals registered. Where coalification is constant, the individual macerals of the hard coals, like minerals, exhibit largely similar elemental compositions and technological properties [20]. However, occasionally they can be further differentiated, if possible. Maceral types can be differentiated on the basis of genesis and petrography (e.g. Maceral: fusinite; Maceral type: pyrofusinite). Maceral varieties can be determined in cases in which the vegetable initial substance is recognisable (e.g. Maceral: telinite; Maceral variety: fungotelinite). In many cases, the macerals do not occur in homogeneous form in material and structural terms, but instead exhibit further internal structural elements. These are then referred to as cryptomacerals (e.g. cryptotelinite) [2, 20]. The macerals, together with the minerals and voids, form the structure of the coals.

The macerals of the vitrinite group (Fig. 31) consisted for the main part of the wood and bark of the original trees. Three varieties are differentiated, depending on the degree of preservation of the cell structures. Unstructured vitrinite originated primarily from the cell content and is known as “collinite”. The cell structure is no longer recognisable. The humous substance is present predominantly in colloidal state. Where the cell walls are recognizable in the structure of the vitrinite, and cell structures are thus identified, if generally only rudimentarily, this maceral is referred to as telinite [4]. Where the cell structures are macerated, reduced in size and deformed, these constituents are assigned the collective term of vitrodetrinite maceral. With the exception of the sapropel coals, collinite, telinite and vitrodetrinite form the matrix of the humic coals.

The macerals of the exinite or liptinite (a term more widely used today) groups (Fig. 31) predominantly comprise the bitumen-containing elements of the coals. They originate from the reproductive organs of the plants of the Carboniferous, and of other resistant plant parts. There were as yet no angiosperms during the Palaeozoic, instead, the predominantly coal-forming plants reproduced by means of spores. The inner dermis of the spores was destroyed after the death of the plants, whereas the epidermis (exine) is extremely durable and largely survived throughout the process of coalification. For this reason, the word “exine” provided the name, exinite, for all bitumen-containing elements in coal. The initial material for the sporinite maceral is the skin of the spores, the cuticles in the case of cutinite, the durable membrane of the epidermis of the plants, and the leaves, in particular, the oleaginous algae in the case of alginite, the waxes and resins in the case of resinite. Where the initial material of exinite is no longer recognisable, and is, therefore, present as “detritus”, these constituents of the coal are grouped together as the liptodetrinite maceral. The macerals of the exinite group form inclusions in the matrix of the humic coals. The matrix does not, on the other hand, constitute the main component of the sapropel coals; the inclusions predominate, algenite in the case of the boghead coals, for example, and sporinite in the case of the cannel coals [4].

The macerals of the inertite group (Fig. 31) exhibit very largely chemically inert behaviour, as in the case, for example, of the beneficiation of coal, coking or extraction. The group‘s name derives from this behaviour. The macerals either originated from thermal and microbiological processes in the swamps (e.g. fusinite and macrinite) or are the residues of fungi (e.g. sclerotinite). Fusinite is present in acicular-fibrous form in the coal and spreads its coloration extensively. It occurs in two types. Fusinite may have originated, on the one hand, from forest fires, and have been deposited as charcoal in the peats of the swamps (pyrofusinite). On the other hand, fusinite was also formed as a result of the decomposition of wood and bark due to attack by fungi (degradofusinite). This fusinite is thus not genuine charcoal, but is, instead, a maceral that has adopted the petrographic and chemical properties of a charcoal due to microbial processes [4, 25, 45]. Like fusinite, semifusinite exhibits a cellular structure, but occupies an intermediate ranking between fusinite and vitrinite. Like fusinite, it also occurs as a pyrogenic or a degradation type, depending on its genesis. Sclerotinite exhibits petrographic and technological properties similar to those of fusinite, but it has totally different origins. Sclerotinite is composed of fungal tissue, the sclerotia [4]. Micrinite and macrinite, on the other hand, exhibit no structures. The cellular structures of the vegetable initial substance have been lost during the process of coalification. Micrinite occurs in the structure of the coal in extremely fine-particled form, macrinite in fine-particled to massive form [2, 19, 20]. A further maceral with no cell structure is inertodetrinite. This is a constituent, the origin of which is no longer discernible, due to decomposition, comminution and conversion. Inertodetrinite is thus a collective term for inertinite constituents which can no longer be classified [2].

4.1.2.3.8 Minerals

In addition to organic macerals, coal also consists of inorganic substance. This is subdivided into four groups.

One part originates from plants which stores biogenic, inorganic minerals in their tissue. The percentage of these minerals is low, however, and does not exceed figures of 0.1 % to 0.2 % [15]. Sulphur is also present in the coal, biogenically, and thus organically, fixed. Sulphur contents in Ruhr coals are generally between 0.6 % and 0.8 % [30].

A second group was formed during the incipient coalification process in the swamp. These syngenetic components were sedimented as clastic material by water or wind or precipitated from solutions. The clastic sediments consist primarily of clay minerals, mica, feldspar and quartz. The chemical sediments are created by the interaction between infiltrating solutions (genuine and colloidal) and the humous constituents of the swamp. In this process, the solutions saturated the organic, and also the sedimented substance. The precipitated minerals, such as the clay minerals (from fresh water only, since only silica and not aluminium are soluble in slightly alkaline seawater), carbonates, sulphides and quartz/chalcedony, resulted in intimate intergrowths [15].

The third group, the epigenetic constituents, are precipitated from solutions during coalification only after the diagenesis of the coal in tectonically generated cracks and crevices and in fissures as a result of the shrinkage in volume of the coal. The minerals deposited are composed primarily of carbonates, silicates and sulphides. The percentages of these admixtures fluctuates greatly locally, due to their genesis [15, 30]. Inorganic impurities, which fall into the coal during winning from the intermediate rock or from the country rock of the roof or the floor as a result of the technology used, must be differentiated from these constituents. In this case, there is generally no intergrowth with the coal. The winning technologies used in the Ruhr area in some cases cause significant by-winning of country rock, with the result that the average gangue content of the ROM coal were frequently above 50 % [35].

The intensity of intergrowth with the coal thus rises from the technogenic, via the epigenetic and syngenetic to the biogenetic inorganic substances. Separation in the processing plant is thus becoming ever more difficult, or even impossible.

4.1.2.3.9 Quantity

It is necessary, in order to estimate the full potential of a deposit, to take into account total resources content. A total coal content of 204 x 109 m3, equivalent to around 270 x 109 t, was determined for the Ruhr within the boundaries stated in Section 4.1.2.1.1, using the methodology examined in Section 4.1.2, Fig. 21 [7, 11, 23].

4.1.2.4 Derived features

The characterisation of a deposit, including the hard-coal deposits of the Ruhr Basin, can be accomplished on formal geological criteria. The chemical, physical and technological features needed for design of machinery and systems can be derived from the geological features thus attained. Further supplementary investigations may be necessary, in cases in which the correlations between the features are not yet known.

The costs of the exploration of a deposit rise in parallel to the number and size of the samples to be taken. Without substantiated knowledge gained from sample-taking and analysis, for the purpose of selection and dimensioning of systems and machinery, it is not possible to quantify the commercial and technical risks involved, however. For this reason, the aim is always to derive from cost-effectively obtainable samples (of rock, coal, etc.) and the necessary analyses (macerals, minerals and their structure) the features relevant for practical purposes, such as, for example, floatability or density of materials, to permit the design of the sorting processes, and hardness, to permit selection of appropriate materials for winning machinery, chutes and silos.

4.1.3 Classification

The hard-coal deposits of the Ruhr region made a decisive contribution to the economic development of Germany. At international level, however, the indicators are now rather modest by present-day standards. Maximum annual production of hard coal in the Ruhr area temporarily reached figures of above 120 million t during the 1930s to 1950s, with a peak of nearly 130 million t/a in 1941, for example [6]. This annual production rate is nowadays almost achieved in the world‘s single largest open-cast mine, Black Thunder, in the USA (>100 x 106 t/a) [51].

The closure of the last hard-coal mine in this coalfield at the end of 2018 will mean that around 10 trillion t of coal were mined from more than 3500 collieries since the start of mining here [18, 34]. Given the current global production of some 8 trillion t/a, this quantity would just be sufficient to cover needs for slightly more than one year.

The total coal content of that part of the Ruhr Basin examined here, some 270 billion t, given the global coal production currently necessary of around 8 billion t, would suffice for just approximately thirty-five years. Even when the extra reserves of coal located in the Münsterland, an additional approx. 170 billion t, are included, the theoretical chronological range is extended only up to around sixty years [53]. New mining technologies would need to be developed, in view of the total depletion of the deposits then necessary, however.

4.1.4 Evaluation

The total coal reserves in the Ruhr Basin within the boundaries stated in Section 4.1.2.1.1 amounted originally to around 270 x 109 t. Of this amount, 10 x 109 t have been mined up to the present day, i.e., less than 5 % of the total coal content of the Ruhr Carboniferous. If these quantities are valued at the highly fluctuating world-market prices obtainable for steam and coking coal, of around 50 to 150 €/t, the total reserves equate to a value of approx. 15 to 40 trillion € and past production of 10 x 109 t to a monetary value of around 0.5 to 1.5 trillion €. Measured against the annual German Gross Domestic Product, these values equate approximately to 5- to 13-fold referred to the total reserves or to around one sixth to one half, referred to total previous production.

On present-day standards, the contributions made by the production of hard coal to the country‘s Gross Domestic Product must therefore be considered relatively modest, despite the fact that this ranking does not apply to the past. The reserves still remaining are nonetheless of a not uninteresting magnitude, however, with the result that it continues to be entirely rational, from a national-economic viewpoint, to invest money in the further development of existing and the evolution of new mining, winning and processing technologies.

In addition to this monetary analysis of the economic significance of the coal reserves of the Ruhr area, the target should also be pursued of recovering these resources – in this case, the coal of a deposit – as completely as possible, since the exploitation of a deposit does not, without doubt, always have only positive effects, such as subsidence, in the case of caving winning, the use of surface land, and the provision of the necessary state infrastructure.

In view of corporate economic, and also national-economic criteria, however, mining has been restricted to those sections of the deposits which could be exploited in rational economic terms, given the technologies and machinery available. The process of balancing the benefits of mining against the disadvantages was, however, ultimately a political one. World-market prices for coal have, for decades, been significantly below the production costs of mining in the Ruhr region. For this reason, the industry could be kept alive only by means of subsidies. Thanks to the consistent further development of technologies and machines, and the concomitant increases in productivity and economic successes, it remained possible to argue politically in favour of these subsidies, particularly on social and economic criteria (employment, assuredness of supplies, maintenance of know-how). Ultimately, however, the imposition of further political aims, such as the reduction of CO2 emissions, had resulted in the abandonment of hard-coal mining as from the end of the year 2018.

Operational and remediation costs will continue to be incurred even after the end of mining. How these costs will compare to the values of the resources produced up to 2018 cannot as yet be estimated with any certainty, although not insignificant amounts are available from the RAG Foundation. As from 2019, an estimated 220 million € annually will need to be expended from these funds for the water-based “tasks for eternity” of the then abandoned hard-coal mining industry in North Rhine-Westphalia and the Saarland, primarily for mine drainage, cleaning of the groundwater and polder management provisions. The costs of the final consequences of mining, such as surface breaks, are not included in these amounts and must be financed separately from RAG [36].

4.2 Perspective

The economic, and also the political, social, scientific and cultural development of Germany has been based for centuries on the extremely numerous – but generally poor – deposits of metallic, energy and industrial mineral resources. Only a few had and have international significance, those of lignite or potash salts, for instance. The most important deposits are those of the hard-coal reserves of the Ruhr area. Since the first documented mention of mining, in 1302, more than seven hundred years ago, they have frequently played a major role in German history, in the context of industrialisation and in times of war and of subsequent reconstruction [13].

In future, Germany, despite having its own adequate reserves, will obtain hard coal solely from abroad. Large deposits located at lesser depths, produce coal from open-cast operations (in the USA, Indonesia, South Africa and Columbia, for example) or from deep mines (e.g. Australia, Poland and Russia) at significantly lower costs. Germany, on the other hand, is no longer politically willing to bear the subsidies necessary for domestic mining of hard coal. A further aspect is climate policy, which sets the target of reducing CO2 emissions in Germany even further in the future. Such mining was stop in 2018. By the end of 2018, the Prosper-Haniel Mine, in Bottrop, the last colliery closed. It is today not possible to estimate the extent to which these political decisions will continue to be viable in the future. The reduction in domestic supply of energy resources and basic chemical feed materials, and a readjusted estimate of the climatic relevance of CO2 emissions, could result in different decisions and thus in different developments.

As sobering as these analyses and as relativising as these evaluations may be, they do not, of course, do justice to the historical, scientific, economic and technological importance of these deposits. Depending on the international political situation, the prospects for Germany in possessing adequate reserves of mineral resources for energy and chemicals in the Ruhr region for any future mining activities which may become necessary may be soothing. The precondition for this, however, would be the further development of existing and the evolution of new mining, winning and processing technologies and of corresponding machinery suitable for mining of the complex geological structures of these deposits.

5 Final note

As the last coal mine in the Ruhr area, the Prosper-Haniel mine in Bottrop on 1 October 2018 promoted coal for the last time. With a large participation of the population and representatives of the Federal Republic of Germany was on 21 December 2018 symbolically set by the last filled lorry coal industry in Germany. Previously, the extraction was terminated underground at the end of September 2018. An SL 750 shearer loader from Eickhoff with a total drive power of approx. 1900 kW and a drum diameter of 2.3 m extracted in the mine field Prosper Nord, underground workings 124, area 008 from Seam Zollverein 1/2 gas flame coal intended for the coking plant in Bottrop. The seam at a depth of about 1130 m (under NN), corresponding to about 1235 m below the Kirchheller Heide with a mean thickness of 3.6 m was unlocked by a longwall of 380m in length. In order to protect the strut against the tremendous pressure of the overburden, newly developed Group C shields with an adjustment range of up to 5.2 m were used. This is how the German coal industry ended for the time being. Glück-auf!

![19 Struktur des Ruhrbeckens (Darstellung an der Oberfläche des Präperms) [9] # Structure of the Ruhr Basin (view at the surface of the Pre-Permian) [9]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_5b468eadd1342c5ad308a901499dce23/w300_h200_x600_y498_Bild_19_NEU-be46e7d7187dba04.jpeg)

![20 Gelsenkirchener Hauptsattel in der Dortmunder Achsenaufwölbung [9, S. 52] # The Gelsenkirchen Main Anticline in the Dortmund Axial Arch [9, p. 52]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_e7e477a601526bdecaa350eb30d085e1/w300_h200_x600_y770_Bild_20-fd3f07fa92e3fcaa.jpeg)

![21 Lagerstättenmodell [21, S. 196] # Model of the deposits [21, p. 196]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_f1d2ab1882d59b8a99ec66f74a6aaf1e/w237_h200_x118_y164_Bild_21-521a917b7c62f571.jpeg)

![23 Steinkohlenvolumina [109m3] (f(Teufe t, Flözmächtigkeit a)) [11,22,23] # Volumes of hard coal [109m3] (f(Depth t, Seam Thickness a)) [11,22,23]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_9f0de12fc24219af1dd8b724d5285de7/w300_h200_x193_y118_Bild_23-f94e171a37fd40ef.jpeg)

![24 Steinkohlenvolumina [109m3] (f(Fallwinkel α, Teufe t, Kohlemächtigkeit a, Fläche südlich Dorsten-Sendener Hauptsattel) [21, S. 264] # Volumes of hard coal [109m3] (f(Angle of Dip α, Depth t, Coal Thickness a, area to the south of the Dorsten-Senden Main Anticline) [21, p. 264]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_df4e566650f381d12726aa87f983df9c/w237_h200_x118_y118_Bild_24-4a4fd9fccabde6d5.jpeg)

![25 Intensitätsverteilung der Bruchtektonik (Verwurf > 10 m an Karbonoberfläche, Streichrichtung parallel Faltenachsen) [9, S. 134/135] # Intensity distribution of fracture tectonics (fault > 10 m at Carboniferous surface, direction of strike parallel to the fold axes) [9, p. 134/135]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_ac77c8b5c9586f5f55cabf588fd75a0b/w300_h200_x600_y365_Abbildung_Intensitaetsverteilung_der_Bruchtektonik_im_Ruhrkarbon-f1df3ca9001d939d.jpeg)

![26 Gesteinsbezeichnung der Kaustobiolithe (Kohlen) [24] # Mineral designation of the caustobiolites (coals) [24]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_9686512696ac1ef22a465649872ce7bd/w300_h200_x191_y129_tabelle26.JPG-2c0d48fa19b50677.jpeg)

![28 Anteil Lithotypen in Kohlenarten [%] [27] # Percentage of lithotypes in coal ranks [%] [27]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_446a49bd38674f12e8590fd04c91757f/w300_h200_x413_y133_Tabelle28.JPG-676a8bc2be51ffa3.jpeg)

![29 Mikrolithotypen [19, 20, 43] # Microlithotypes [19, 20, 43]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_2bd9cf3a741d09386a731190d76c62b4/w300_h200_x298_y284_Tabelle29.JPG-c162bb00905c9586.jpeg)

![30 Maceralgruppe, Mikrolithotyp, Lithotyp und Kohlentyp (Hauptanteile) [1, 2, 4,19, 20, 24, 43] # Maceral group, microlithotype, lithotype and coal type (main contents) [1, 2, 4,19, 20, 24, 43]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_4ac6c0ca8d45e416d43108323e820c8f/w300_h200_x396_y207_Tabelle30.JPG-b3d2464e5f60e568.jpeg)

![31 Maceralgruppen und Macerale [19,20,54] # Maceral groups and macerals [19,20,54]](https://www.at-minerals.com/imgs/1/4/0/8/2/0/3/tok_cbd77578daf88b4607691808822e7f17/w300_h200_x188_y168_Tabelle31.JPG-bb65cfe098703b94.jpeg)