Belt-conveyor transfer stations

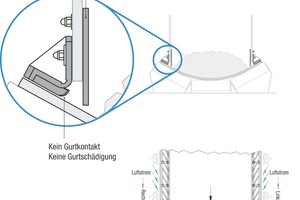

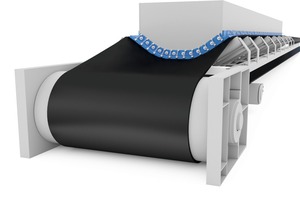

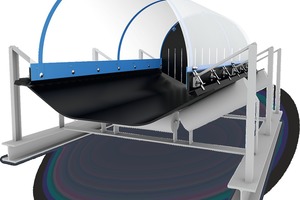

Whether operating underground or on the surface: spillages and the escape of dust are a bugbear that affects all sectors. To put an end to both without, at the same time, expanding exponentially the maintenance work needed on the side sealing systems installed in the vicinity of the transfer stations for this purpose, Wilfried Dünnwald brooded long and hard over a range of technical principles. His course of fundamental home study of the various potentials included a thorough process of elimination. What, indeed, would have been the point of developing a technical solution essentially similar to those already installed? Wilfried Dünnwald’s personal inventor’s “product scope statement” for this reason also focused on eradicating the universally known detrimental side-effects of existing systems. On the criterion of finding new routes in the areas of wear, zero maintenance and service-life, only a non-contact system and the Venturi principle could ultimately be considered. This basic concept was followed up by numerous tests, which gradually proved ever more promising as they progressed. The prototype of the now patented AirScrape first saw the light of day in 2012, and laid the foundation stone for successful series production. In 2015, this initial success emboldened Wilfried Dünnwald to himself take charge of production and to set up his own company, ScrapeTec Trading GmbH. Around the globe, some 1000 belt transfer stations are now protected by ScrapeTec solutions. “One of the first AirScrape series-production models has been in daily use in a dolomite plant since 2013, and still continues to fulfil its task with great reliability,” the system’s developer is justly proud to confirm. Other products that later followed the AirScrape under the DustScrape and TailScrape names in all cases evolved from the specific needs that became apparent to specialist development experts from on-site installations or were expressed by customers.

“It is very stimulating, always finding the right solution. We have now established that transfer points offer more positive potential for this than was previously thought. My primary interest, of course, is in the technical aspects, but our products now also convince supervisors in Financial Controlling and specialists in occupational health and safety. And that is very satisfying and motivating for the whole of our workforce,” Wilfried Dünnwald is pleased to relate, concerning the success of his company’s innovations. ScrapeTec’s sales and marketing manager, Thorsten Koth, also regularly has the opportunity to note just how intensively the factors of occupational health and safety, efficiency, cost-savings, environmental protection and energy-efficiency – in short: sustainability – are linked to the installation of an AirScrape system. His current impression: “AirScrape and its current sister products have turned out to be dependable self-marketers, and they are in demand internationally. Our presence at attendance trade fairs has raised international awareness of these products significantly. Such an offensive approach has also helped us in consolidating the ScrapeTec presence, via newly co-opted local partners.”

Also worthy of note is much positive feedback from users: “All of them confirm how quickly the installation pays off, provided the operator is not discouraged by the somewhat higher initial investment costs. The rewards are immediate, and are found in the benefit of working with a dependable, almost wear-free system, genuine freedom from dust emissions at transfer points, improved working conditions for the workforce and lower wear on belts, pulleys and the equipment as a whole. Not to be forgotten: an energy-efficiency bonus. Anyone wishing to gain an impression of the functional mechanism of AirScrape without travelling long distances can find very illustrative videos of the system in action - on YouTube, for instance.” With the flaring up of the Corona pandemic and its restrictions, ScrapeTec also accelerated the implementation of its previously planned remote-working programme. This segment provides, for example, web-seminars and video conferences, in which problem cases can be visualised on site using a camera and then discussed with ScrapeTec’s experts. This saves both time and costs in the run-up to implementation.

ScrapeTec Trading GmbH’s references include not only many SMEs, but also well-known industry names such as Knauf, K+S, Holcim and Saint Gobain, to mention only a few. The fact that AirScrape is now in service on belt-conveyor transfer points around the globe is solid proof of the system’s capabilities under even the toughest climatic conditions.

scrapetec-trading.com

scrapetec-trading.com