Belt Alignment Controller Now Available with Shorter Roller Arm

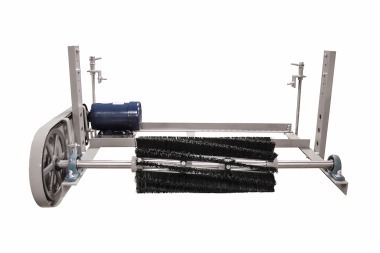

The Model TA Belt Alignment Control by Conveyor Components Company is a rugged and dependable deviation switch for belt conveyors when they become misaligned due to an unbalanced load, high speed, belt damage or other problems (Fig.). The controls are commonly used in mining operations, coal and iron ore handling operations, on assembly lines, and other bulk material handling applications. In the event of belt run off these belt alignment controls can save time and money by alerting the operator of the problem and/or shutting down the conveyor belt completely.

Each control is made of durable cast aluminum housing with a steel, red epoxy coated spring loaded roller arm with a stainless steel shaft. The standard roller arm is 10“ in height and can now be special ordered with a shorter arm length of 5“ for enclosed or hooded conveyors where space is limited. The arm is adjustable up to 90 ° in both directions without damaging the controller and should be installed approximately 1“ from the conveyor on both sides of the belt. The microswitch actuation points are adjustable from 0 ° to 45 ° by a simple change of the actuating cam. The roller arm automatically returns to the normal position when the belt is back on track.

The Model TA is available in NEMA Type 4/4X for outdoor use and is corrosion resistant. Explosion proof models are available. The units are available with up to two 20 amp SP/DT microswitches, normally open or normally closed contacts, to control up to two separate output functions. wo DP/DT microswitches are available upon request. All models are UL and CUL Listed. Conveyor Components Company is an ISO 9001 Registered Company.