Increasing Efficiency and Security for Conveyor Belt Systems

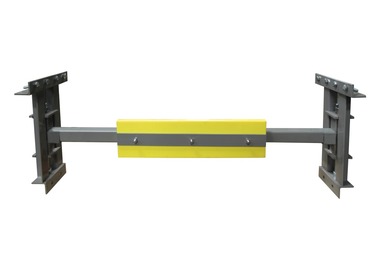

The Model DB belt rip detector, manufactured by Conveyor Components Company, is a mine-duty and quarry-duty belt rip detector, which operates on a simple cable pull concept. When a belt flap or tear, or a foreign obstruction such as a wrench or screwdriver or piece of rebar has pierced a conveyor belt, the cable releases the activation ball from its protective socket and trips the device. The outputs of the Model DB can control up to four separate circuits, depending on the model chosen, as either SP/DT or DP/DT microswitches are available. These alarms can include one for machinery shutdown, which minimizes further conveyor belt damage, and one for alarm. The Model DB is a very cost effective unit, in both design and installation that provides similar benefit to the very expensive embedded coil devices on the market.

This standard housing construction is corrosion resistant cast aluminum, with an optional polyester or black epoxy powder coating. The protective rubber boot on the cable assembly keeps the activation mechanism clean and functional, and is easily replaced if damaged.

//www.conveyorcomponents.com" target="_blank" >www.conveyorcomponents.com:www.conveyorcomponents.com