Belt weighers in mobile plants with mobile access

What is the current handling rate, what is the daily output or are there any breakdowns – these are data plant managers and managing clerks want to be informed about which anywhere at any time.

Built-in weighing machines are the classical weighing system for this. They acquire rock materials within the conveying process without any additional working expenditure. Belt weighers are increasingly used also in belt conveyors of mobile screening and crushing plants.

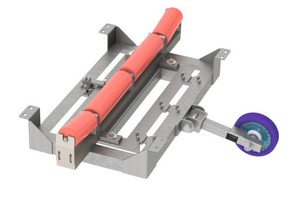

For this reason, MTS MessTechnik Sauerland has developed a built-in belt weigher particularly for these plants. The use of a belt weigher in a mobile screening or crushing plant makes great demands on engineering. Strong vibrations of the conveyor belt during the operation and a very small space for installation, particularly due to the possibility of being hinged for transportation, are challenges to be met both by the design of the weighing machines and by the weighing electronics.

The MTS belt weigher EBW 10-HD Mobil with the evaluation electronics ModWeigh FBW meets all these requirements. The findings and experience related to many installations of the last five years have been incorporated into the development of the weighing machine. In the meantime the current version of the EBW 10-HD Mobil has already become part of the product program of the Kleemann Company as regards mobile screening and crushing plants. The weighing machines from MTS are distinguished by a very low design and an extremely torsionally stiff frame ensuring a high reliability and measuring accuracy. A safeguard against overload and a transport locking device protect the weighing cell. The compact and rugged weighing electronics ModWeigh FBW supports the efficiency of the belt weigher operating with a high scanning rate and efficient filter adjustments.

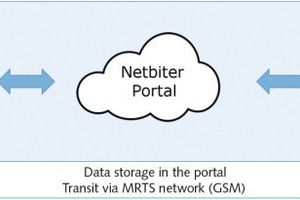

Mobility is also in demand as regards the access to measured values and operating parameters of the plants. Whether stationary or mobile belt conveyors – a call from the tablet, handy or PC is enough and the measured results and operating parameters of the MTS belt weighers are available any time and irrespective of the location.

This is possible due to a small additional device on the belt weigher that transmits the measured values without any cable. For this purpose, the weighing electronics of the belt weigher are directly connected with a communicator, which cyclically sends the measured data to the Netbiter portal by means of an MRTS network, to which access is possible via a standard web browser from the tablet, handy or PC.

The portal is responsible for archiving of the data and enables the monitoring and administration of these data. The pages can be configurated according to the in-house requirements, measured values can be prepared graphically and reports can be generated automatically. Thus comfortable tools are available for an advanced operating data collection and real time monitoring. The alarm management is another advantage. After reaching a fixed limit, an automatic notification is given by SMS or e-mail.

The Netbiter system offers a complete data management for any weighing system you like. It is also possible to operate various belt weighers at a location by one communicator. Of course, the access to the portal is protected by a corresponding user identification.

The installation of the system is relatively simple and can also be carried out later for existing belt weighers. Network specialists are not required for this work. However, the technicians at MTS will be glad to support you.

Conclusion: Belt weighers provide reliable measured results even in mobile plants. The access via tablet, handy or PC offers a lot of mobility regarding the operation, the safe monitoring and the operating data acquisition of the plants according to the requirements. To equip the weighing machine with the communicator is a small investment resulting in great benefit.

$(LEhttp://