Design of Heavy-Duty Idlers for the

Upper Run of Belt Conveyors

Part III: Operational Design of an Idler

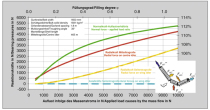

The requirements to be met by heavy-duty idlers in respect of, for example, running resistance or noise emission, are steadily increasing. These operational requirements are derived from the growing importance of the energy demand or the increasing requirements for emission control. Idler running resistance, for instance, determines on average 5–15 % of the energy demand of a belt conveyor and therefore the energy costs or also the maximum possible centre distance and therefore the consumption of a production operation. The level of the noise emissions affects the environmental integration of the belt conveyors in the natural environment. The steady development of this primary operational behaviour has led to belt conveyors further improving their competitive advantage over non-continuous conveying systems. In connection, for example, with other technical measures concerning the energy demand of belt conveyors [7, 11] or other extensive measures for emission control [4, 10], the operational behaviour of belt conveyors systems has been optimized considerably in recent years. Following on from the observations from Part I “Idler Requirements” [1] and Part II “Engineering Design of Idlers” [2], in Part III the operational design of idlers is described based on the above-mentioned circumstances.

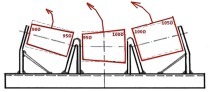

1. Introduction With the growing requirements for the efficiency and environmental compatibility of conveying systems, focus is increasing on the optimization of belt conveyor components (Fig. 1). Energy consumption and emissions of dust or noise are key criteria for the goal of increased efficiency so as to improve the environmentally compatible integration of belt conveyors in their environment from an already high level. Technical advances are reflected in the development of the individual components too. Outstanding developments are found, for example, in the optimization of the energy...