Design of Heavy-Duty Idlers for the Upper Run of Belt Conveyors

Part I: Idler Requirements

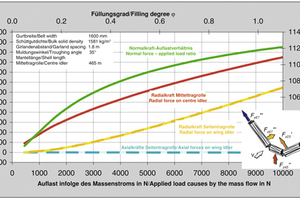

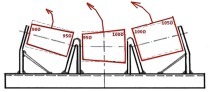

Alongside investment and operating costs, the technical behaviour of belt conveyors is becoming increasingly important for their operators. High mass flows and heavy materials, e.g. sandstone, result in very high loads on belt conveyors and their idlers. The design of the idlers must ensure that they can handle these loads in order to achieve an acceptable idler service lifetime. In addition, the specific energy requirement and the associated CO2 emissions hold similarly high importance as that of noise and dust emissions. Rising energy costs and stricter demands for emission control mean belt conveyor operators must meet increased requirements to enable cost-efficient conveying. As a contribution to the optimization of belt conveyor engineering, in three parts the requirements for idlers (Part I, below), their structural design (Part II) and their operative design (Part III) are described comprehensively for B1600 belt conveyors with mass flows to 10 000 t/h.

1. Introduction

Compared to alternative transport options, the transport of bulk solids on continuous conveyors boasts significant advantages with regard to availability, cost efficiency and flexible application in field operation. Belt conveyors can transport large quantities of bulk solids over long distances, negotiating great differences in height, in sometimes difficult operating conditions. Environmentally friendly integration of belt conveyors is possible in the field conditions as they have limited adverse impact on their environment. Low specific power consumption, a high transport...