Digitising minerals quarrying

The corresponding display and analytical software for minerals-winning organisations is marketed by Caterpillar in cooperation with French start-up Redbird. Since 2016, it has been undergoing further development under the auspices of Airware – a start-up in which Caterpillar has a shareholding. The basis takes the form of ground reference points. The quarry is then aerially photographed by a drone. This process generates hundreds of images. The Redbird software package is compatible with the commercially available rotary- and fixed-wing drone types used for acquisition of aerial images. Redbird uses orthophotography to compute from the individual aerial images a single 3D model with a resolution of 3 to 4 pixels per cm. “The actual art of the matter consists of displaying the 3D data generated on a user-friendly web interface complete with automatic analyses. Only this gives the user an overview of his quarry, enabling him to make better decisions more quickly on the basis of data analyses,“ is how Bernhard Tabert defines the benefits of this system.

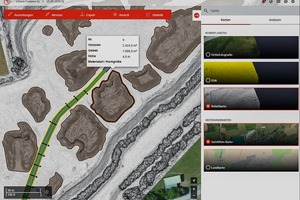

Internet access, a log-in and a password are all that is needed for access to Redbird when operators of earthmoving machinery need to know how their winning operations are progressing. They then have access to their data. The quarry is shown cartographically and in colour in a 3D view – and details can be examined with high accuracy by means of a zooming function. Quarrying advance between any two overflights or an overflight and a planning event (such as a mining approval plan, for example) can be displayed, and the differential volume calculated.

Use on the computer is easy. “Anyone who can handle a PC mouse can use Redbird. The focus of Redbird is not on the surveyor, but rather on the quarry operator – the actual situation at his quarry is made visible for him,“ continues Bernhard Tabert, himself a university-qualified surveyor. Above all, operators of multiple quarries can remote observe each individual location easily and comfortably from their office. In detail, various winning-point statistics and their indicators, which are of importance for productive extraction, can be viewed. Piles of extracted material in the storage yard, classified by type of material and particle size, are included in an analysis report. The volumes of such piles can be automatically calculated using the PC mouse, simply by “dragging” a polygon around the pile displayed.

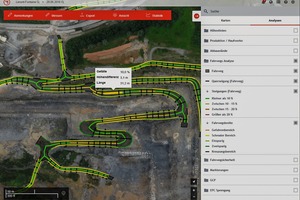

One of the greatest efficiency factors in quarries is the quality of haulage routes, since these are critical in attaining the targeted production rate. Corresponding vehicle routes which are in good condition and well maintained are necessary here – ultimately, the haulage vehicles are required to attain maximum possible speed on these roads. The visually displayed haulage routes, complete with gradients and road widths, enable users to see, for example, whether planned annual production rates for a quarry can actually be achieved on the basis of the haul trucks‘ round trips. “A one million tonnes of material annual target for a quarry would, for example, mean 15 400 round trips by a Cat 775G of 65 t payload capacity. The question that then arises is how many hours will be needed for these 15 400 round trips? And how can the transport routes be improved, to reduce these cycle times?,“ Tabert explains.

The Redbird software detects quarried edge planes, haulage routes (complete with road widths), transverse gradients, inclines and base widths. This information is displayed for the user in colour, as a function of limit values, in order to permit more rapid recognition of any deviations. “Operators can then see, for example, whether a haul truck can operate continuously in top gear, or whether gradients or serpentine bends in the haulage route will necessitate the use of a lower gear, causing a drop in speed,“ Tabert elaborates. Safety verges and boulders used as road-edge markers are also analysed, complete with their height, being automatically detected by the system by means of algorithms. The width of the haulage roads, which ultimately determines whether double-lane haulage traffic will be possible, can also be analysed. “With a single-lane haulage road, passing bays will be necessary, and where multiple haul trucks are in operation, there will be repeated stops en route, with short interruptions to operation, with negative implications for round-trip cycle times,“ the product manager notes.

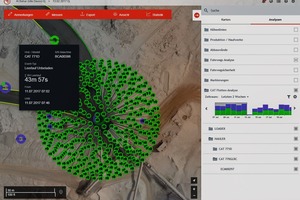

Cat machine data, which is transmitted via Cat Product Link telematics boxes, is also integrated into Redbird. Around 14 000 Cat earthmoving machines are currently equipped with a telematics box. Product Link, installed as standard in virtually all Cat machinery, is now also available for other manufacturers‘ earthmoving machines and vehicles. It can be used to review operating hours, GPS positions, described idling times and fuel consumption. Works and production managers thus at all times have an overview of when a machine has stood idling for how long. “This generates an incredible savings potential which only very few have up to now been able to express in concrete figures. Who is aware, for example, that a Cat dumper truck causes costs of around 60 € for an hour of idling, when fuel, servicing and depreciation are taken into account? Take a look at a fleet of several Cat dumper trucks operating in a quarry, and filter out all the idling events of more than 10 minutes, and you will soon have 500 hours of idling annually – and that means 30 000 € of lost income for the company,“ Bernhard Tabert calculates. But you firstly have to be aware of this.

And even more important, is making crews aware of how much expense they cause by simply letting the engine of an earthmoving machine continue running, to keep the heating or air-conditioning going, or just because they want a quick cup of coffee. The substantiated data now available makes it possible to illustrate what idling periods not caused by production circumstances can be avoided. And this is Bernhard Tabert‘s message for visitors to the steinexpo: “In the next few years, drone data will contribute greatly to educating operators, and will provide them with an important tool for the achievement of significant cost savings.“

//www.zeppelin-cat.de" target="_blank" >www.zeppelin-cat.de:www.zeppelin-cat.de