Double-deck linear vibrating screen with 72 t tare weight for 10 000 t/h ore slurry

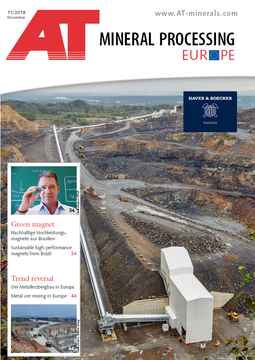

In many regions and countries, there are large copper and gold surface mines that generally use SAG mills for processing ores. In parallel operating lines, a large number of screens is used to extract many thousand tonnes of copper, gold, molybdenum and other metals.

The SLK4390WX screen measures around 5.5 m in width, 10.5 m in length and 6.5 m in height. It is the first double-deck linear vibrating screen with four DF704-exciters, twin drive with two 90 kW motors and variable speed control. With a total weight of 120 t, a vibrating weight of 72 t and exciters, which together generate the power of four aircraft engines, it is not surprising that the screen is lovingly known as the “Beast”.

Owing to its size, a machine on this scale transfers strong vibrations into the foundations and load-bearing structures. An isolating frame is used to combat this problem. The isolating frame ensures that only a fraction of the exciter force is transferred into the load-bearing structures and foundations during operation.

The plant design requires that screens regularly have to be taken out of the production line – e.g. to change the screening surface. To minimize the down time, a redundancy principle was designed for maintenance purposes. With the help of a transport frame moving on tracks, the complete screen including isolating frame, drive motors and water spraying system are removed from the production line. At the same time, a second identical screen is moved into operating position and started up with a “Plug & Play” function.

In addition, the screen is equipped with a CONiQ condition monitoring system. This provides the operatives with regular information on the screen‘s operating parameters. This information can also be checked by Schenck Process by means of a remote connection.

The entire project was realized with regional and global involvement. The screen was designed and engineered by Schenck Process in Australia. Schenck Process manufactured the machines at sites in Germany, Australia and China. Final assembly and trial runs were performed in China. From there, the two screens are then delivered direct to the place of operation.

“The application and engineering know-how from Schenck Process was crucial in this project. An understanding of the behaviour of the feed material combined with rugged and durable screen machine design were the key to success. The company only has all that if it can draw on many years of experience in screening and processing equipment,” reports Jan Ehrenfels, Manager of Screening Systems Europe at Schenck Process. When it comes to maximizing process and product efficiency, optimizing the availability of equipment or extending the lifecycle of plants, Schenck Process calls on its extensive expertise to offer customized solution strategies.

//www.schenckprocess.com" target="_blank" >www.schenckprocess.com:www.schenckprocess.com