Dust-, spillage- and maintenance-free skirtings

Conveyor belt skirtings for transfer points as a basis for further developments

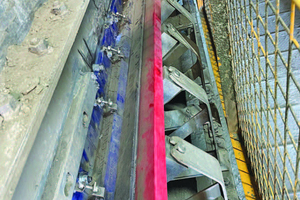

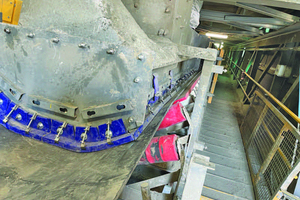

ScrapeTec Trading GmbH started with the AirScrape as its first product. The aim of company founder and developer Wilfried Dünnwald in developing this sealing system was to achieve maximum dust reduction at transfer points of bulk material handling systems. The AirScrape includes special skirtings at the transfer point which hover freely above the conveyor belt and use the air flow resulting from belt movement. They are mounted laterally with an air gap of approx. 1 – 2 mm to the belt at the transfer point. Lamellas integrated in the AirScrape provide a so-called “Venturi effect” which results in an air suction from the outside to the inside. Dust or other fine material can thus not escape to the outside. This particular dust-reducing feature of AirScrape is esteemed worldwide wherever this special system is installed as belt skirting for transfer points.

The experience gained from the use of AirScrape has led to the development of further products supplementing the ScrapeTec Trading GmbH portfolio. All solutions relate to the transfer points of conveyor systems. Take, for example, the DustScrape. This dust protection device with its sturdy filter cloth is installed in front of the transfer point in the direction of belt run and catches coarse dust and particles. It has a self-cleaning function. The DustScrape spans the conveyor belt on its entire width and ensures optimum dust reduction in this position. In the rear area of the transfer, the TailScrape is applied. Like AirScrape, the TailScrape works according to the Venturi concept and without contact to the belt. Owing to its blade structure, it matches the contour of the belt trough precisely and serves as a customized rear belt sealing. Together, the AirScrape, DustScrape und TailScrape ensure dust reduction in perfection. Here, it becomes apparent that the original idea during development of the AirScrape, namely a maximum dust reduction at transfer points, has been innovatively thought through in subsequent products.

“Our drawing card is clearly the AirScrape,” says Thorsten Koth, Sales & Distribution Manager of ScrapeTec Trading GmbH. “But customers quickly recognize the synergy effects when the three dust reduction specialists work together.” Thorsten Koth supports customers worldwide. “Many interested people have seen the AirScrape on Youtube and have quickly recognized the advantages. Then they want more information or even on-site consulting. With the power of digital communications, companies find us from every corner of the world. With conference formats like Teams, we can present the whole system ourselves and do consultations. But we also have distributors in some countries for consulting. Or sometimes we travel ourselves.”

CODELCO, Chile’s largest copper producers, also apply the AirScrape product, as other major players, for example in Spain. It is important for Thorsten Koth to emphasize that small and medium-sized enterprises in particular also benefit from skirting solutions as the AirScrape. “Without making a large investment, immense costs can be saved in operation. This simply increases the profit.”

Minimum investment – maximum cost savings

“Of course, I cannot present new clients with a cost-benefit calculation of our customers. No one would appreciate a look behind the scenes. But the calculation is quite simple: you take the acquisition costs for the AirScrape-equipment. There are no assembly costs; this can simply be solved in-house. These costs are then compared with other costs: Maintenance work, cleaning work, repair costs and new acquisition costs for worn belts and skirtings. With the application of our skirting solutions, the costs for the items mentioned are reduced considerably. We hear from our new clients in Peru that the belt sealings applied before had to be replaced due to wear every fortnight and that each replacement resulted in a standstill of 3 hours. So 26 weeks times 3 hours a year: 78 hours. And every company knows what every hour of downtime costs. According to a rough calculation of the Peruvians, the AirScrape thus already paid off after only one months. And now it has been in service for 17 months already.”

Owing to the contact-free and thus frictionless mode of operation of skirtings like AirScrape and TailSrape, the costly purchase of new belts necessary because of common sealing-friction damage is avoided. Interested customers should record the costs for a fiscal year which resulted from dust load (also the costs due to sickness-related absences), material spills, cleaning and exchange of skirtings and belts. This provides a good starting point to realize the economic benefits of the ScrapeTec skirting solutions.

The Essential AIR Seal Dust Containment Combination

A cement production operator based in the Port of Brisbane needed to deal with the following problems:

Excessive dust emissions, posing major OHS issues

Material spillage

Belt support and belt sag issues

Minimizing production shutdowns

The cement company’s core business focuses primarily on unloading key cement materials utilized for cement production. The finished cement products are then later packed into 20 kg bags, and bulk raw materials are also loaded into trucks to service building, construction, and road development projects.

A comprehensive site inspection was conducted by ScrapeTec’s Area Technical Representative; it was noted standard chute sealing was used together with a basic clamping system positioned outside the chute. The current skirting system in place and lack of inner skirting was insufficient and failed to contain excessive dust emission and material spillage experienced at the transfer point. Dust and spillage levels were high and constant during ship unloading process. This provided zero visibility of the 70-metre-long conveyor tunnel and had greatly affected maintenance team’s ability to monitor efficiencies and bottlenecks in the production process.

Site Management was mindful that material spillage was eroding the operator’s bottom line, with additional cleaning up costs incurred to clear the spillage piles and prevent any tripping/slipping hazards. Dust extraction trucks were also necessary to clean the walkway and the tunnel on regular base. Dust poses a serious OHS hazard to workers, the environment, and nearby communities; suppressing dust emissions was therefore high on the agenda and required rectification to minimize any production downtime and improve site availability.

After a presentation in 2020, ScrapeTec implemented the AirScrape® application on site. ScrapeTec’s Technical Area Representative supervised the AirScrape® installation and performance when it was initially trialled in the ship’s unloading transfer chute. Extremely satisfied with the outcomes achieved at this transfer point, the operator welcomed the implementation of the Essential AIR Seal Dust Containment Combination – phase 2 of ScrapeTec’s recommendations. This entailed a few necessary adjustments before the installation of AirScrape®, TailScrape® and ceramic K-Containment Seal® was installed and fully operational within the chute area.

To ensure maximum performance of AirScrape®, K-Sure® Belt Support System, a vital component of the overall solution was installed in order to avoid the issues of belt sag between the impact rollers. A smooth straight and flat belt surface kept the AirScrape® lamellas continuously in the right position with no physical belt contact. TailScrape® worked synergistically with AirScrape® and provided outstanding sealing at the rear and K-Containment Seal® delivered on its promise as the first line of defence and effective against dust and spillage.

The newly applied AirScrape® waterproofing system brought the following advantages:

Problem free transfer point, dust emission and material spillage reduced by 98 %

No belt damage, no future adjustments and maintenance is necessary

Product performance expectations exceeded

More upgrade opportunities in other transfer points

Maintenance teams are also thrilled to report, prior to the phase 2 recommended installation, there was extremely poor visibility of the tail end of conveyor from the head chute. With dust and spillage under control visibility along the 70-metre-long conveyor is now vastly improved. “The Essential AIR Seal, Dust Containment Solution is a huge improvement in comparison to our initial setup, no belt damage and no ongoing maintenance is required,” reported by Site Manager.

And finally, the operator has cemented its plans to upgrade all the chutes in the conveyor stream from ship unloading to the stockpiles, representing five transfer points in total.

Hall 4, stand B12