Cost-efficient measures for reducing dust

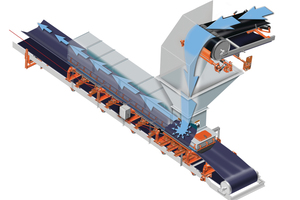

Effective ways to avoid and reduce dustSummary: The following article introduces possibilities for plant operators to realize cost-efficient measures for reducing dust based on a systematic procedure. Pivotal here is an integrated approach to the causes and possibilities. The release of dust at belt conveyors or at transfer points can be essentially attributed to four mechanisms, which are explained in the following. A key parameter is the air flow through the transfer point. Shown are one calculation method and a comparison between theory and practice.

1 Analysis of the starting situation

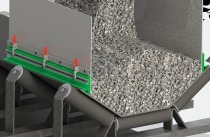

“That’s just the way it is, there’s always been dust. And the extraction system has never worked properly.” Such complaints about bulk solids conveyor transfer points can often be heard in the field.

In fact, the causes for the generation of dust are complex: volumes and particle sizes of the emitted dust depend on many parameters. Accurate dust measurements are costly, as the emissions are diffuse, so it is not possible to draw any direct conclusions regarding individual emission sources. Plant operators often rely on a visual impression to decide where the...