Elastic motor support for constant tension

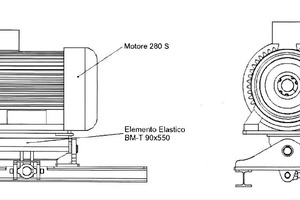

Tecnidea Cidue has supported the constructor in the planning and in the development of a “custom” Elastic Motor Support, for the electric motor that operates the mill. These Elastic Motor Supports have a single preloading system realized through a 250 Bar hydraulic cylinder. Moreover, this elastic element was studied in order to integrate itself in the supporting parts of the machine, thus optimizing the spaces and reducing the encumbrances. Another peculiarity of this elastic element is having an internal thrust bearing support, which prevent the radial maladjustment between the axis of the external square tube and the axis of the internal square pin, caused by the pull of the belts.

This slipping can provoke both an irregular transmission of the torque and a quick wear of the belts and the pulleys. All the elastic motor supports BM-T allow a constant tensioning on the belts, avoiding therefore manual adjustments. This avoids unnecessary costs caused by both operator intervention and the standstill of the machine.

The above described system was also implemented with anti-vibrating elements type VIB AN in order to support the entire mill and to avoid therefore the propagation of the vibrations to the other structures of the machines and to the ground. VIB suspensions type BT-F and VIB big ends of the connecting rod type TB were used for vibrating screens realized through connecting rod-crank system.

The “core” of this application is the rubber in which this motor support is realized. The natural rubber used by Tecnidea has the feature to develop a high twisting rate and to maintain a high elasticity in order to absorb the vibrations coming from the hammer mill. In all the belt transmissions, the torque is transmitted through friction. It is therefore very important that a tension is always present on the belts, thus allowing the maintaining of a force of friction. This force must be strong enough to avoid the slipping on the pulleys.