Granulation of powdered coal

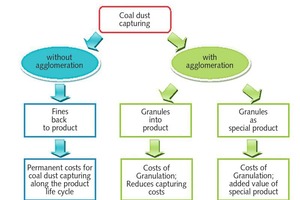

Environmental protection with profitSummary: This paper addresses the subject of coal dust. This is often captured in dedusting systems to avoid emissions with the associated impairment and hazards. Studies at HAVER ENGINEERING GmbH have shown that processing of the powdered coal fraction to non-dusting particle sizes can be realized simply in technical terms.

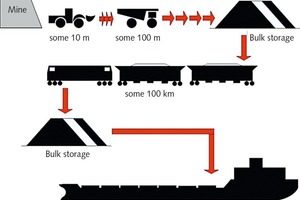

Lignite and coal are key fuels in global power supply. In global terms, around 30 % of the primary energy demand is covered by coal [1]. Energy consumption and the corresponding demand for energy raw materials is growing, especially with the steady increase in the global population and the industrial development of emerging economies. Worldwide, around 8 bill. t coal is mined annually [2, 3]. But before the coal gets from where it is extracted to the place where it is used, it already has several material handling stations behind it. The transport chain sketched out in Fig. 1 illustrates the...