Filtering pigments and fillers gently but thoroughly

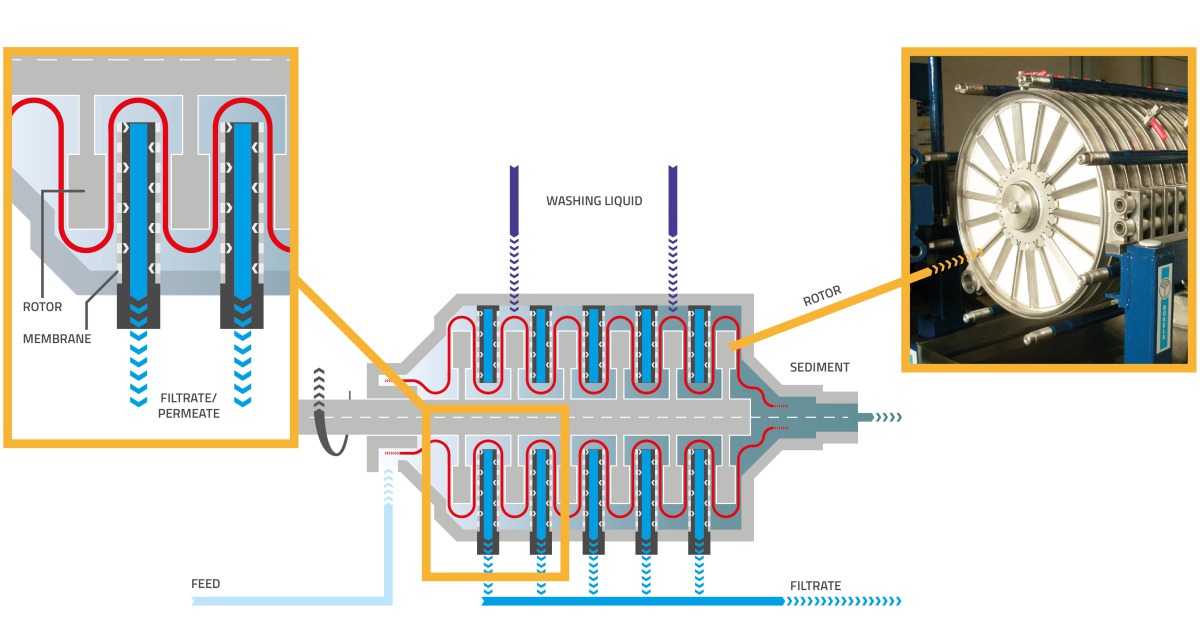

1 Dynamic crossflow filtration allows a concentration up to six times higher and a up to ten times more throughput when filtering pigments and fillers

1 Dynamic crossflow filtration allows a concentration up to six times higher and a up to ten times more throughput when filtering pigments and fillers

© BOKELA

Extremely fine-grained suspensions with a particle size of 2 µm or smaller often are a challenge to filtration systems of any kind. Especially, if the filtrate is supposed to be absolutely particle-free and highly concentrated. “Many companies are already satisfied with a lower concentration than they could actually achieve,” states Klaus Neumaier, Senior Process Engineer/ Technology Design at Bokela. And that even though higher concentration within one cycle does not only save time and resources, but also money.

2 The secret inside BoCross filter: ideal physical conditions thanks to a perfect use of the shear gap principle

2 The secret inside BoCross filter: ideal physical conditions thanks to a perfect use of the shear gap principle

© BOKELA

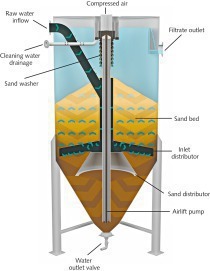

At Bokela, the experts rely on the principle of dynamic crossflow filtration. Contrary to the conventional crossflow process, the tangential overflow of the filter surfaces is created by rotors, when it otherwise would have to rely on the geometrical flow control in the apparatus. The fluid follows the shear gap when flowing with a high velocity gradient over the filter medium. The shear forces at work allow only a very thin, static boundary layer of solid particles. Thanks to the shear gap principle, this particular process faces almost ideal physical conditions and thus, reaches up to six times higher concentrations than a traditional crossflow filter.

Furthermore, the throughput is higher, too. “With a BoCross Dynamic Filter, you achieve a continuous, intensive, and effective product washing with up to ten times more throughput than with other filter systems,” Neumaier explains. Even highly viscose suspensions with 25 000 mPas can be processed as spreadable paste without any air pockets.

Casting a glance inside the BoCross filter reveals how this gentle but thorough separation process works: within a closed chamber system, the filter modules are arranged as a series of discs. While the suspension flows from chamber to chamber, its concentration is continuously increased, as filtrate is drained in each chamber. Neumaier adds: “The construction of the filter allows us to add wash water or process fluids in each chamber.” Another feature of this membrane filter is its compatibility with various filter media: micro filtration, ultra filtration, special sieve composite panels, or metal media. Consequently, the BoCross filter and the dynamic crossflow filtration can be used for a wide range of industries and fields. “Whenever the task is to filter pigments or fillers which are particularly fine-grained or with particularly small particles, this method often allows to get better results in a proven process,” says Neumaier. This is applicable to calcium carbonate, but also works with regard to titanium dioxide products. “And even washing out reaction products or residue is done with incomparable efficiency and reliability.”

Pigments and fillers deriving from fine white minerals can be found in many sectors and industries. The wide spectrum of applications is mirrored in the diverse requirements regarding the product: specific crystalline forms, particle shapes and sizes. Depending on the area and industry, the focus is on a different aspect. A complex separation process, however, is always at the solution’s core in order to achieve the desired results. “Dynamic crossflow filtration as performed by the BoCross filter is a highly efficient, very gentle, and absolutely safe method”, concludes Neumaier.