From the mine to the product

From 13th to 15th March 2017, the seminar “From the Mine to the Product” took place in the Institute of Geosciences and Geography of the Martin Luther University Halle-Wittenberg (MLU) in Halle on the Saale. The seminar was organized by the MLU Department of Mineralogy/Geochemistry in collaboration with FLSmidth.

More than 50 participants followed the invitation to this international seminar to exchange experience and discuss requirements relating to the complete process for the production of building materials – from the mining of minerals to the manufacturing of the building materials. In addition to lectures by scientists from research institutes concerning the latest results of scientific research in the raw material and building materials sector, a series of presentations from industrial representatives also focussed on new developments in equipment engineering and plant construction.

After the participants had been welcomed, the event began around noon with the opening presentation under the title “Different strategies for alternative cements by CO2 reduction” by Prof. Dr. Herbert Pöllmann, Deputy Head of the Institute of Geosciences and Geography of the MLU. In his lecture, Prof. Pöllmann discussed alternative methods of cement production, focussing on alternative clinker phases, alternative raw materials, additional cement materials and alternative reaction pathways. For example, by increasing the specific surface, the reactivity of the clinker phase can be increased and the number of cement phases in the application can thus be reduced. Other suggested approaches are an additional activation of the clinker phase or the replacement of limestone by CO2-free natural/industrial raw materials.

Raw materials

The subsequent presentations on the first day were devoted to the topic “Raw Materials”. Michael Hidding of FLSmidth Australia spoke about “Sampling - the key to successful quality control”. He stressed that although sampling sometimes involves considerable cost, the need to obtain truly representative samples is not understood. Even the best analytical methods are useless if the sampling is incorrect. The volume and form of the sample can be decisive – every particle in the stream of material must have the same chance of becoming part of the sample.

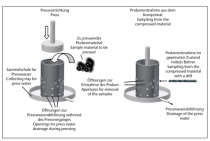

After that, Dr. Roger Meier of FLSmidth A/S, presented “Innovation in X-Ray sample preparation”. The use of automated sample preparation is a particularly effective way of greatly reducing the error. In addition, a higher output of samples improves the statistics of the results. When preparing the tablets, it is important to ensure that the sample characteristics are not changed during the process, e.g. during the tablet pressing.

Stepping in for his colleague Rob Chapman, Michael Hidding spoke on the subject of “How Essa® sample preparation equipment can support you in your daily work”, in which he presented various sampling devices.

The last presentation of the day came from Oliver Jakobs of FLSmidth A/S, and Karl-Heinz Rüttiger-Barth of Hauk & Sasko Ingenieurgesellschaft mbH, and was entitled “FLSmitdth BulkExpert unmanned operation system – a success story”. In this lecture, the possibilities for automatic stockpiling and reclaiming were described very comprehensively and in a practice-oriented manner. Usage of a fully automated process enables the achievement of a uniform stockpile contour and optimum homogenization of the material.

Then Dr. Stefan Stöber of the MLU led a tour of the institute and showed the participants the laboratories of the Institute of Geosciences and Geography. The seminar was accompanied by a poster session with a number of contributions, which could be visited in the institute area during the coffee breaks. The first day was brought to an end with a bowling session for all participants as a way of “warming up” the personal contacts.

Quality and process

The morning session of the second day was entitled “Quality and process”. Mette Dobel of FLSmidth A/S began with the question “Do you control your quality well enough?” The focus here was on the possibility of automated sample processing, from sampling to analysis to evaluation, in combination with the appropriate software to optimize the raw meal composition.

After this, Dr. Marcus Paul of Dyckerhoff AG, Buzzi Unicem gave an insight into “Process monitoring in cement production”. He dealt in great detail with the possibility of cement phase analysis – with the subsequent aim of being able to predict the expected properties of the finished product on the basis of the on-line data analysis.

In his second presentation, Dr.-Ing. Roger Meier of FLSmidth A/S spoke on the subject of “Unique total solutions for the cement and lime industry”, discussing the characteristics of at line and online quality analyses and the possibilities of different analytical methods and equipment.

The contribution by Thomas Neumann of Schwenk Zement KG dealt with “Disturbing effects on the clinkerization of opc-clinker”. On the basis of practical considerations, he particularly examined the influence of the increasing amount of secondary fuels used in the cement production process.

Mette Dobel of FLSmidth A/S and Dr. Bernd Eber of Rohrdorfer Zement presented two case studies concerning “High level control of blending of raw materials”. On the basis of results obtained in industrial operation, they demonstrated that correct and continuous sampling has a clear and demonstrable effect on the quality of cement clinker.

To conclude this block of topics, Thomas Jennewein of FLSmidth Pfister GmbH spoke on the subject of “Dosing to perfection – based on case studies”

Analytical techniques

The second part of the day focused on analysis methods and presented new developments and further developments of sensors and analytical methods in the mineral sector. This series of lectures began with the presentation “AllScan - The innovative, smart PGNA analysis approach” by Steen Tokkesdal Pedersen of Realtime Instruments (RTI). With its roots in the Australian coal industry, RTI developed a PGNAA analysis using a lower radiation level for the coal, mineral and cement industries.

“Optimize your mine from ore to metal” was the title of the presentation by Uwe König of PANalytical B.V. He focussed on Partial Least Squares Regression (PLSR), a statistical evaluation method, in order to predict “hidden” properties directly from the raw materials. On the basis of examples, such as the analysis of bauxite, he demonstrated the method’s practical feasibility.

The subsequent lectures were devoted to different analytical methods. Henning Rehbock of Thermo Fisher Scientific presented “The new Thermo Scientific™ CB Omni™ Fusion Online Elemental Analyzer”. Rainer Schmidt of Bruker AXS showed “How QPA in minerals & mining profits from dedicated sample preparation”. A high-resolution portable X-ray diffractometer was presented by Bert Kinneging of xplorex GmbH, in his lecture “The PLANET; Experience portable high resolution X-ray powder diffraction”. The portable case met with a very positive response in view of the fact that it enables e.g. an initial rock analysis to be carried out on the spot, even in rough terrain. The presentation by Petra Mühlen of SpectraFlow Analytics, “SpectraFlow Online NIR Analyzer: applications in the cement and minerals industry”, showed the applicability of this NIR technology for the analysis of mineral phases on the basis of an impressive reference list. The second seminar day ended with a discussion on “NIR-spectroscopy in quality control of the new hydraulic binder celitement”, led by Dr. Carolin Lutz of the Karlsruhe Institute of Technology (KIT).

The evening event took place in the “Technisches Halloren- und Salinenmuseum Halle (Saale)”, the Technical Museum of the Brotherhood of Salters. Dressed in the traditional costume of the salters‘ trade association “Gemeinschaft der Halloren”, a member of the museum staff gave a brief historical outline of the tradition of producing salt by brine boiling in the city of Halle. Afterwards, the boiling of brine was demonstrated. 100 t of evaporated salt per year are still produced in the museum today and the product is very popular in the region. During dinner the participants had ample time to further discuss the topics of the day.

Research and Development

The third day of lectures gave an overview of the status of research. A number of lecturers from the MLU presented their current work and projects, with Dr. Ronny Kaden of the MLU Halle opening this series of lectures with “Improvement of cements using carboxylic admixtures”. Dr. Tobias Beirau of the MLU Halle described “Spectroscopical methods in the characterisation of raw materials, products and residues”. His work involves the analysis of mineral phases, mainly with Raman and NIR spectroscopy, and making comparative studies of the pure phases.

“Requirements for materials in case of CO2 storage applications” were discussed by Dr. Andreas Neumann of the MLU Halle. The challenge of CO2 sequestration lies primarily in the reaction of the CO2 with the surrounding material.

Sabrina Galluccio from MLU Halle described the “Synthesis of CSA cements using differnt raw materials and routes”. It is the formation of the hydrate phases depending on the respective raw material that determines the later properties of the binder. The lecture paid particular attention to analysis of the CSA phases.

“Phase identification, quantification and correlation with technical properties in large sets of XRD measurements” was the topic of the presentation by Dr. Torsten Westphal of the TU Bergakademie Freiberg. He compared the Partial Least Squares Regression with the Rietveld Analysis as analytical methods for the determination of cement phases.

Research into the “Mineralogical carbonization reactions during cement hardening” was presented by Kristoff Svensson of the MLU Halle.

“Perovskite and their use - minerals and technical use” was a fundamental and very illustrative lecture concerning the story of perovskite’s discovery, its mineralogical properties and its technical uses, e.g. in the cement industry and in the production of solar cells, presented by Dr. Stefan Stöber of the MLU Halle.

“A new highly precise temperature control in the range of 0-80 °C for XRD sample holders” was explained by Dr. Michael Ecker of Mesicon Scientific Consulting. A final summary by the organizers from the MLU and FLSmidth concluded the seminar and the very worthwhile exchange of knowledge and experience in Halle (Saale).

$(LEhttp://