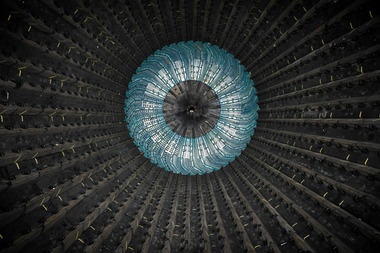

Grinding mill components for copper and gold mine in Asia Pacific

Metso Outotec has signed a services contract for the delivery of four ball mill upgrade packages to a copper and gold mine in Asia Pacific. The value of the order is approximately € 19 million, and it has been booked in Minerals’ Q4/2021 orders received.

Equipment refurbishments lead to improved machine availability and safety

Equipment refurbishments lead to improved machine availability and safety

© Metso Outotec

Refurbishment projects for older, existing assets are an efficient method to extend a mill’s operating life, increase energy efficiency, and minimize waste and plant downtime. Additionally, equipment refurbishments lead to improved machine availability and safety by delivering the latest available technology. “The customer’s performance objectives were achieved by offering a technical solution which increased the operating volume of the mill and allows for future process optimization. Providing these thirty+ year old mills a new lease of life is exciting for Metso Outotec and builds on our sustainability promise of delivering circular offerings,” says Jonathan Allen, Senior Vice President, Grinding, Bulk and Pyro business line of Metso Outotec.