Herding GmbH Filtertechnik

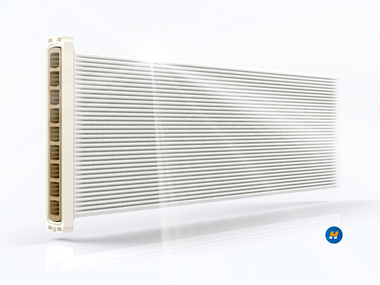

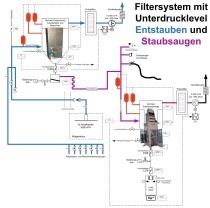

Herding Filtertechnik, the specialist for innovative filter systems, has managed to create an ultra-compact filter system for the efficient extraction of dust at all stages in a very wide range of processing lines – the Herding® DELTAFlex (Fig.). This means that all the filter units in a production line can be operated and maintained easily and at low cost. A safe disposal system for all the different types of dust via a central system can be integrated without any problems.

The core feature of the Herding® DELTAFlex generation of filters is the inherently rigid sinter-plate filter – a patented in-house development. Pure surface filtration ensures that even ultra-fine dust particles are reliably retained. The sintered rigid body is extremely hard-wearing against abrasive solids and also against mechanical and chemical loads. In terms of durability the sinter-plate filter lasts well over 10 years, depending on the specific process. Adhesive solids are effectively prevented from sticking to the filter surface by automatic precoating. For explosive atmospheres a range of structural and preventive explosion protected versions are also available.

The Herding® DELTAFlex series enables extremely efficient dust extraction for volumetric flows of up to 400 000 m³/h. The sinter-plate filter offers outstanding cleaning properties and constant pressure loss for stable extraction performance of the highest standard. The dust discharge can be configured to meet all safety-relevant requirements.

Hall 4; Stand 230