Infinitely adjustable

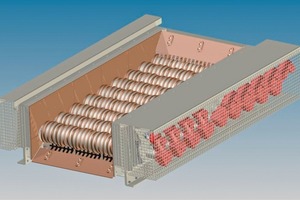

The roller screens produced by August Müller GmbH & Co. KG (AMR) are used primarily for pre-screening and cleaning, and also for coarse grading in pre-crushing installations, of „dirty“ feed materials such as limestone (Fig. 1), basalt, granite, coal, salt, etc.. The company has now developed, under the VR 35 product name, a hydromechanically adjustable roller screen based on the principle of the adjustability of spindle spacings of 35 mm of the previously determined basic setting and particle size. Unlike the long tried and proven chain-driven synchronous operation of the individual spindles in the AMR system, drive is by means of individual electric gear motors. The result is that the rhomboid disks are now no longer arranged in a synchronised line but are, instead, staggered vis-à-vis the round disks. Individual drive using electric gear motors has the advantage that, via frequency converters, each spindle can be controlled and operated at its own individual speed, thus reducing clogging. The ease of maintenance and repair resulting from individual drive systems and couplings should also be emphasised. Particular attention has, of course, also been devoted in the development of the VR 35 to cleaning of the round disks. The scrapers centrally located below the individual spindles are moved at the same ratio as the individual spindles, i.e., they are included in the adjustment mechanism.

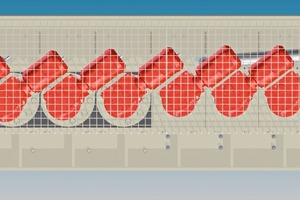

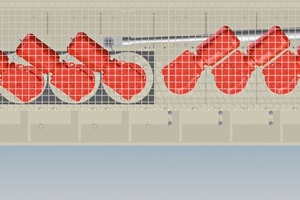

The final four spindles of each VR 35 feature gap adjustability (Fig. 2). Hydraulic adjustment is performed via the electrical control system for the hydraulics. Flow dividers ensure that precisely the same flow of fluid is fed at precisely the same fluid pressure to the two hydraulic cylinders. These double-acting cylinders are thus secured by means of fluid pressure at a constant setting with a fixed pressure. Infinite adjustment is thus possible with the machine running but material feed stopped (Fig. 3 and Fig. 4). It is recommendable to install a split chute with reversible belt conveyors underneath the roller screen, in order to exploit the adjustability of the latter as effectively as possible. Like the standard model, the recently developed VR 35 version is also available in a range of lengths and widths, and with various thicknesses for the machined square-section spindles. The VR 35 is produced as a single-stage machine and can be installed in virtually any pre-crushing line in place of a conventional mechanical screen or stepped bar screen.