Innovative conversion of the SCHADE Wagon Charger ensures a

continuous unloading process

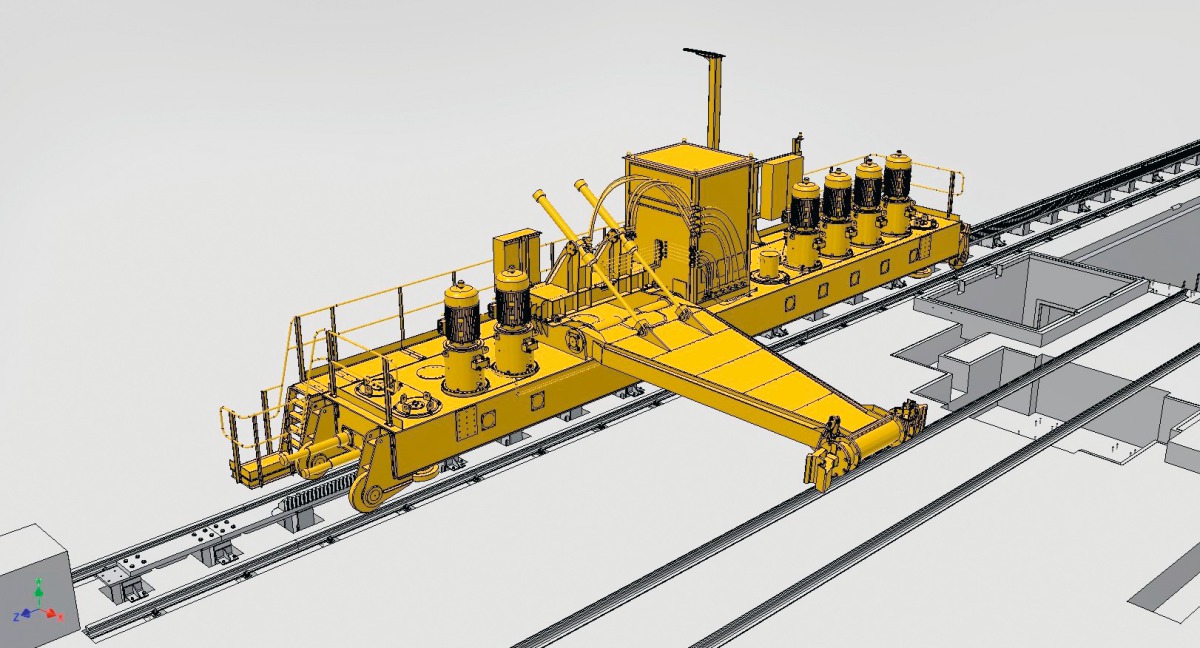

3D depiction of the new reinforced SCHADE Wagon Charger for Taman Seaport

3D depiction of the new reinforced SCHADE Wagon Charger for Taman Seaport

© Illustration: SCHADE

Currently the defrosting operation takes around 20 minutes per train, increasing the unloading time from 36 minutes to 56 minutes in winter months. As the current design capacity of the Wagon Chargers is limited to 36 wagons, each incoming train of 72 wagons needs to be split into two strings of 36 wagons by the port operators, with each shortened string requiring the 20 minutes defrosting time. In order to reduce the unproductive thawing time and thus increase the unloading efficiency, the Wagon Charger capacity will be increased from 36 wagons to 72 wagons. The required 20 minutes defrosting time is now applicable to the longer train with twice the number of wagons. Because of the increased Wagon Charger capacity, once the first 36 wagons of a 72 wagon train have been unloaded, the port operators have the option of adding a further 36 wagons to the rear of the train to effectively provide continuous unloading, without the need to stop for thawing.

In order to implement this technical solution with a minimum of investment costs, SCHADE worked closely with OTEKO Portservice to design Wagon Chargers for which many components and equipment parts of the existing Wagon Chargers can be used. The new components which will be required are being fabricated individually and will be supplied end of this year. After installation of the parts into the existing Charger, which will be taken out of operation while this is carried out, the first extended Wagon Charger will be ready in time for the winter season 2021/2022. Afterwards the second Wagon Charger will be converted.