Keeping air clean with innovative filter and dust collection technology

W ith the introduction of the new PowerCore® technology and the development of more effective filter media, Donaldson has succeeded in realizing higher efficiencies coupled with a lower consumption of resources. With the use of Ultra-Web® and Dura-Life® filter media, not only can filtration efficiency be improved, the energy consumption of the dust collection system can be reduced. Filters with Ultra-Web® and Dura-Life® technology are standard equipment in almost all Donaldson Torit® DCE® dust col-lectors and used as replacement filter elements for dust collection systems from other manufacturers (Fig. 1).

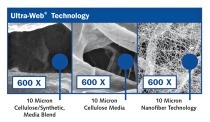

Ultra-Web® is a nanofibre filter made in an electrospinning process that produces a very fine, continuous fibre measuring 0.2–0.3 µm in diameter. The Ultra-Web® filters achieve a retention rate of 99.9 % for dust particles from 0.2–2 µm. The retention rate for dust particles of 0.5 µm is 99.999 %. The filter medium therefore meets very high industry standards and corresponds to the BIA classification M. The filter medium is available in various grades (e.g. flame-retardant version) and in combination with different substrates (e.g. synthetic polyester media). Consequently, the innovative medium covers a wide range of applications from traditional dust collection to the extraction of laser fume and powder coating to sensitive applications in the production of chemicals.

Filter bags made from the Dura-Life® filter medium have been standard equipment in Donaldson Torit® DCE® dust collection systems for years and are also used extensively in equipment from other manufacturers, as, compared to equipment with conventional filter media, they impress with a two to three times longer lifetime. On the smooth surface of the Dura-Life® filter medium, the dust particles are captured so efficiently that cleaning is much easier, as it can be performed with lower pressure and lower mechanical load. Despite the longer lifetime and higher filtration efficiency, the differential pressure remains stable. The longer lifetime therefore does not come at the expense of higher energy consumption.

Donaldson’s systems can be designed as central cleaning systems or decentralized dust collectors. Built-in units are also available, and integrated solutions can be supplied “off the peg”, e.g. for low flow rates or for defined applications, such as silo installations. An example of this is the PowerCore® dust collector, a flexible system with a wide range of application. The compact size (Fig. 2) is a crucial advantage for the conversion and extension of existing plants.

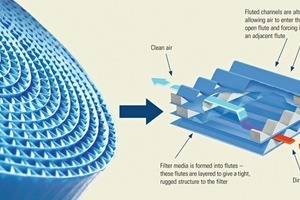

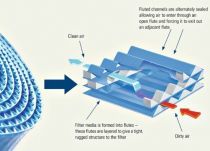

The core element of the PowerCore® technology are the filter packs. As filter medium, the proprietary Ultra-Web® nanofibre filter media is used, formed into flutes that collect particles without depth-loading (Fig. 3). This dust collection technology is the precondition for “downsizing” compared with filter bags or cartridges. With Ultra-Web® it is possible to generate a more efficient dust cake on the filter surface than it is possible with conventional fabric filters made of depth-loaded standard 540 g/m2-polyester. Application-specific versions of the filter packs are available for special requirements, e.g. to conform with ATEX directives.

The PowerCore® filter packs have a low weight and can be easily handled by one person. A PowerCore® filter pack can be replaced in just two minutes. At the same time the filtration efficiency can be increased considerably. Independent laboratory tests confirm: PowerCore® filter packs reduce emissions by up to 78 % compared with standard polyester bags. In field tests it has been showed that the pressure losses are lower thanks to the use of the Ultra-Web® nanofibre filter medium. This has a positive effect on the energy consumption.

On the website //www.donaldsonToritDCE.com" target="_blank" >www.donaldsonToritDCE.com:www.donaldsonToritDCE.com, a tool is available to calculate and configurate individual dust collection solutions. After the most important parameters have been entered, the toolbox calculates the cost savings that can be achieved by the use of the Ultra-Web® nanofibre high-performance filter cartridges.