Key technology for efficient copper ore processing

The mine operator CUDECO is banking on innovative allmineral technology for processing their native copper. As of mid 2013, the Chinese state company SINOSTEEL will bring into operation ten jigging machines type alljig® for treatment of various particle sizes as an integral part of their “Rocklands Group Copper Project”. allmineral’s technology will be the core equipment within this high-tech plant, which will produce high grade copper as well as marketable cobalt, gold, pyrite and magnetite concentrates over the next decades.

After having performed a number of tests on allmineral’s pilot equipment (minijig® und alljig® P-400) in independent laboratories located in Perth, CUDECO decided in favor of the allmineral technology. In an area of a size of 16 ha just 17 km west of Cloncurry in Queensland exploration results indicate prospects of up to 30 million t of various minerals with high metal content. It is planned to mine and process existing resources in one of the technically most advanced processing plants in the world. During the first years, the focus will mainly be on mining native copper next to the surface with an expected maximum copper content of up to 20 %. In addition, copper sulfide and -oxide with traces of gold and silver will be mined, along with pyrite with traces of cobalt, gold, and silver as well as magnetite. All of these minerals will be processed and upgraded to high quality products for the global market.

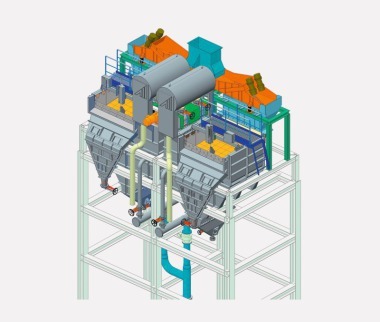

On behalf of CUDECO, SINOSTEEL will build a unique processing plant utilizing the most advanced technologies available. A total of ten alljigs® designed and manufactured in Europe will play a key role in the process. Four coarse jigs (8-40 mm feed size, capacity of 110 t/h each) as well as three medium jigs (4-8 mm feed size, capacity of 55 t/h each) and three fines jigs (1-4 mm feed size, capacity of 45 t/h each). The state of the art air-/side-pulsed design of the alljig®-jigging machines allows for optimized jigging stroke generation along with high energy efficiency. The alljigs® in Queensland have an operational capacity of up to 740 t/h and produce a remarkable high grade concentrate.