Managing bulk solids with innovation and reliability

The MARTIN ENGINEERING Corporation was founded in Neponset, Illinois/USA, in 1944, and since then it has manufactured pneumatic vibrators for unloading bulk solids containers. In the 1970s Martin Engineering (ME) developed and patented air cannons to promote material flow by preventing caking and clogging of material. In the 1980s the company focussed increasingly on conveyors and developed the first customer-specific belt cleaners, which have been continuously further developed since then. Parallel to this, ME developed other products for conveying. For example, belt aligners, problem solutions for transfer points, and dust suppression systems. Systems for air-supported conveying and a comprehensive array of services, like the MartinPlus maintenance programme, are also part of the company’s portfolio. Today, ME is one of the world’s leading suppliers of systems for making the handling of bulk solids cleaner, safer and more productive.

With the Center of Innovation for Bulk Solids Handling which was opened at the headquarters at Neponset, Illinois/USA, in June 2008, ME has its own facility for global research and development. Thanks to the close collaboration with universities, associations as well as with customers, products and processes are optimized and further developed to improve productivity and cost efficiency in industrial operations in which cleanness, operational and work safety as well as efficiency are basic requirements in the production process.

Since its founding, the company has extended its activities all over the world. ME has subsidiaries in Brazil, China, India, Indonesia, Mexico and South Africa, with licensees in Australia and Canada. The German subsidiary was founded in 1987 in Walluf near Wiesbaden and now has over 50 permanent employees. To mark its 25 year anniversary, the company arranged a big celebration for employees and customers, which was also attended by the son of the company founder and Chairman of the Board at ME, Edwin H. Peterson with his family.

At a customer symposium prior to the celebrations, customers were given the opportunity to find out about new strategies and innovations for enhancing the safety of conveyors combined with improvement of their cost efficiency. Alongside Michael Hengl, who as Managing Director of the European subsidiaries welcomed the guests and outlined the corporate philosophy, the speakers included Werner Baxman as Sales Manager for Europe and Todd Swinderman, former Chief Technology Officer, President and Board Chairman at ME, who continues to support the company as an independent consultant in important strategic matters.

During the anniversary celebrations at the German subsidiary in Walluf, Ulrike Mehl, Editor at AT INTERNATIONAL, spoke to Michael Hengl, Managing Director of Martin Engineering Europe:

Michael Hengl: ME has been active on the European market for more than 25 years. One reason was certainly the ties of the owner family to Europe. The name Peterson has its roots in Sweden. In addition, the company certainly did not want to just supply the European market from the USA, but actively take part in business in Europe itself.

Germany was chosen as central location. As well as the German company, there are independent subsidiaries in France, England and Turkey. In addition, there is a branch in Spain and naturally other distributors in Europe that do not belong exclusively to ME. From Europe, the company looks after a total of 109 countries, e.g. the countries in North Africa and the Near East. With our European site, we are closer to these countries than our headquarters in the USA.

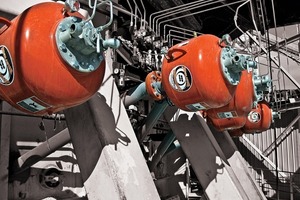

Michael Hengl: Basically the entire range of products is sold on the European market, i.e. all products that positively influence the flow behaviour of bulk solids and thus make the transport of bulk solids cleaner, safer and more efficient. This ranges from the cleaner technology and transfer technology to the compressed air cannons. Since the beginning of 2012, we have been selling vibration technology in Europe. Our unbalance motors have already been used in the USA for a long time in, for example, oil and gas extraction or in underground mining. In the meantime, we are supplying our unbalance motors to the gold mines in Turkey to support the screening systems used there.

Naturally, there are special product developments that we only supply in a few countries in Europe, because the appropriate industry and therefore the demand is not found everywhere. In lignite surface mines in Germany, for example, very large and high-speed belts are in operation. For these we have developed the SHD cleaner, which is specially designed for harsh operating conditions and operates for several months without maintenance. Otherwise, however, you can only find this branch of industry in Poland, so accordingly sales specifically of this cleaner are limited to Europe.

Michael Hengl: Only around 20 % of the products are supplied from the USA. These are generally customized or speciality products. But generally we prepare the manufacturing drawings for our products and get them manufactured externally. We work with several regular suppliers, according to the motto, “Think global, act local”. Assembly and installation are then completed under the direction of ME.

Michael Hengl: We do have a separate department for research and development in Europe too. Our biggest department, however, is “Engineering” with product specialists who further develop our products and process engineering for the local market but also work on product innovations. In 2012, we have introduced various new products, of which three were developed exclusively here. That is, for example, the MARTIN® safety valve for air cannons, which offers increased safety for maintenance processes and protects the air cannons against the ingress of material. Another product – a brush cleaning system for rail vehicles – was specially developed for a specific customer.

Michael Hengl: We offer this service under MartinPLUS® for the three areas of installation, maintenance and process optimization – here we make long-standing contracts, but also accept orders on short-term basis, e.g. “on call”. In addition, an option is available for us to take over complete operation of the belts, the customer paying us on the basis of availability. This type of contract will in my opinion play an increasingly important role in future. We are seeing how it is becoming more and more difficult to build up a good team of specialists. When we look at Brazil, here the percentage of really well-trained staff is low and therefore the percentage of services higher than here with us in Europe. After-sales service has grown substantially in importance for us in recent years.

Michael Hengl: Basically, we are growing almost exclusively organically, with only few acquisitions. For this reason, we have relatively uniform growth over the entire range of products in Europe. Naturally, that can differ from year to year, depending on the project situation, but overall it is very balanced. In 2011, for example, we registered a comparatively large increase in sales related to belt conveyors, on the other hand in 2012 we received a big order for air cannons, which led to stronger growth in this product area. Otherwise the growth depends on our access to the markets. It often starts with belt cleaner technology, then the same customer may also have a problem with the conveying or storage of bulk solids, and then needs several products from our portfolio, like for example our air cannons or dust suppression systems.

Seen globally, the service area is certainly making up the largest share in overall growth.

Michael Hengl: In our market segment, new countries will emerge and develop a strong economy. In this context, I am including, for example, Turkey or also North Africa. These countries will take over part of the business that we have in the core countries today. Not to forget the areas of safety and plant availability.

The market will certainly grow in volume. After all, our company has a very wide portfolio covering many areas. We do have very good competitors, some of whom, however, concentrate only on a certain branch of industry, e.g. the cement industry or the coal industry. These companies will be forced to look around for other areas of business and go into new markets with new products. That will certainly be a challenge for us too.

By and large we see our broad basis as an opportunity, and from the view of the customer this is certainly an advantage. The customer only has to work with one partner. The trend on the customer side is increasingly towards turn-key plants. And we can resolve an array of different problems with our products.

We have come through the difficult times quite well because we put a great deal of thought into our planning. We have a very good global network, and accordingly we have developed a good early warning system for ourselves. From our experience, we can say when something kicks off in America, it takes about six months to arrive here with us – no matter whether it is a positive or negative development. For that reason, here in Europe, we were able to prepare ourselves for the worst. We did not have to make any staff redundant nor did we have to resort to short-time working. We have used the time to look at our processes, we have further qualified our staff and continued to serve and support our customers. Even if we did not receive any orders during this time, it was still important to support our customers with advice. With the result that after the crisis the customers wanting to make investments, which are inevitably flowing again, showed themselves to be loyal and placed their orders with us. And that on a scale that we could never have anticipated. We have therefore been able to register a steady upwards trend over several years and the collapse from the years 2008 and 2009 has plainly and simply been levelled out.

Finally, it is gratifying for us to see how our customer support over this long period has led to such a positive outcome for our company. And as you can see today, our customers were happy to accept the invitation to our anniversary event, celebrate with us, and drink to our further fruitful and partnership-based cooperation.