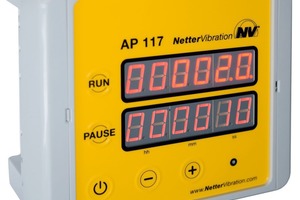

New control with extended operating mode

The new AP 117 control from NetterVibration provides an extended operating mode (Fig.) that enables connected vibrators to be regulated in such a way that it is easily possible to save energy and reduce continuous sound level. The new AP 117 control allows setting of the duty cycle of the connected vibrators according to operational requirements. The advantage: there are no limits to the free division of the operating intervals on a per-second basis. In this way, vibration can occur according to the requirements of the individual operation. Short vibration phases distributed evenly across the day as well as repeated, long-lasting vibrations are only two of many possibilities that can be set with the AP 117.

Targeted vibrating always makes sense whenever processes are subject to a certain cycle time. For example, the problem of bridge formation in silos, which occurs only after a certain time, can be solved in time by compressed air impactors of the PKL series. Not only does this save energy costs, because a clocked vibration phase can reduce the operational hours of the vibrators, but also mitigates background noise. When developing the AP 117 particular importance was attached to simple, intuitive operation of the device. Special programming skills are not required. The clear display is easily legible.

The idea behind the AP series (timer) is to automatise processes easily so as to save time and energy, to spare operating equipment and material and to reduce the emitted continuous noise level of the controlled devices. The new control is designed to meet the individual demands of a production process and to operate the connected vibrators only when actually needed.

There are numerous fields of application for the AP 117: it controls the draining of tanks and the conveying of bulk material; moreover, it optimises the compaction of powders time-wise for a perfect result.

Hall 1, Stand 539

$(LEhttp://