On the safe side with granulation technology

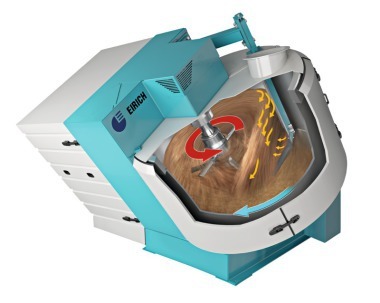

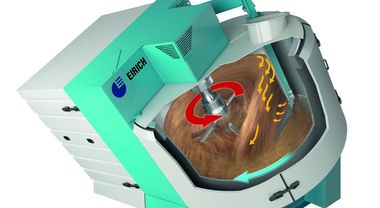

Many industrially used substances are made up of very fine particles. This can be caused by the manufacturing process, or it can be down to usage requirements, as is e.g. the case with pigments. Dust avoidance and good dosing accuracy can be achieved by transforming the dusts into granulates. One of the methods for transforming powdery substances into granulates is build-up granulation in mixers. In many industries this is done with EIRICH mixers. Depending on the material, it can be used to manufacture granulates ranging in diameter from 100 µm to 5 mm.

In sizes from 1 to 3000 liters, the EIRICH mixers used for granulating in batch mode or continuous mode have just one moving tool, the so-called rotor; the rotating container transports the material that is to be mixed to this tool. This means that there is no need for fast-running and fast-wearing choppers. The rotor can run at tool speeds of up to 30 m/s. This makes it possible to generate high shear forces and distribute liquids quickly. As a result, it is possible to produce a comparatively uniform granulate, and the range of grain sizes can be controlled within wide limits. If necessary, granulates can be coated with fluids or solids at the end of the granulating process, e.g. for hydrophobing. If organic solvents are used, explosion-proof versions of the mixers are available. Customer tests at the EIRICH test center have shown that, in some cases, it is even possible to granulate finely dispersed substances without the addition of liquids or chemical aids; examples of this include bismuth vanadate or zinc oxide.

With this technology, processors of titanium dioxide in particular now have access to a cost-effective method for exploiting the advantages of granulates over powders and preempting potential regulations relating to titanium dioxide dusts.

Companies who are interested can find out the best or most cost-effective conditions for a granulating process at the test center in Hardheim or at one of the other sites of the EIRICH Group. This is a simple way to verify the cost-effectiveness of the granulating process and criteria such as freedom from dust, flow properties and redispersibility.

//www.eirich.de" target="_blank" >www.eirich.de:www.eirich.de