Preventing accumulation in mining hoppers and chutes

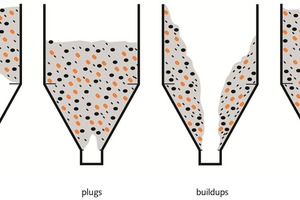

“Most systems suffer from some amount of accumulation on vessel walls, which can reduce material flow, decreasing the ’live’ capacity of the vessel and the efficiency of the bulk handling system overall,” observed Brad Pronschinske, Global Director of Air Cannons Business Group for Martin Engineering. “The accumulations tend to take one of several forms: arches, plugs, build-ups or ’rat holes’. If they become severe enough, flow problems can bring production to a complete stop,” Pronschinske continued.

Build-up versus throughput

Even well-designed processes can experience accumulations, which have a significant impact on output and profitability. Changes in process conditions, raw materials or weather can all have an effect on material flow, and even small amounts of accumulation can grow into a serious blockage. Beyond moisture content, there are many causes of raw material buildup on vessel walls. Some metals contain naturally occurring magnetic properties. Nearly 90 % of the earth’s crust contains silica, and the sharp crystalline structure can contribute to buildup. Other factors can include the surface friction of the silo walls, the shape of the vessel, the angle of the slope and the size of the material being loaded.

Lost production is probably the most conspicuous cost of these flow problems. Shutdowns to clear the restricted flow cost valuable process time and maintenance hours, while wasting energy during re-start. Refractory walls can be worn or damaged by tools or cleaning techniques. When access is difficult, removing material blockages may also introduce safety risks for personnel. Scaffolds or ladders might be needed to reach access points, and staff can risk exposure to hot debris, dust or gases when chunks of material are released.

Many of the most common problem areas for accumulation are classified as confined spaces, requiring a special permit for workers to enter and perform work. The consequences of untrained or inexperienced staff entering a silo or hopper can be disastrous, including physical injury, burial and asphyxiation. Disrupted material adhered to the sides of the vessel can suddenly break loose and fall on a worker. If the discharge door is in the open position, cargo can suddenly evacuate, causing unsecured workers to get caught in the flow. Cleaning vessels containing combustible dust – without proper testing, ventilation and safety measures – could even result in a deadly explosion.

Professional cleaning

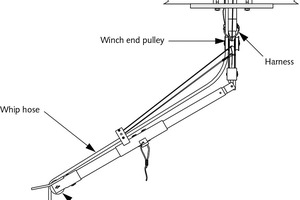

“While some large facilities choose to make the capital investment to purchase their own cleaning gear to clear process equipment and storage vessels – as well as train personnel – others are finding it more sensible to schedule regular cleanings by specially-trained contractors,” said Pronschinske. There are a few types of equipment used for this purpose. One operates like an industrial-strength “weed whip,” rotating a set of flails against the material in the vessel. This approach eliminates the need for confined space entry and hazardous cleaning techniques, typically allowing the material to be recaptured and returned to the process stream.

The whip can be set up quickly outside the vessel, and it’s portable enough to move easily around various bin sizes and shapes. Technicians lower the device all the way down through the topside opening, then start at the bottom of the buildup and work their way up. In extreme cases, a “bin drill” can be used to clear a 30.5 cm pathway as deep as 45 m to start the process.

Flow aids

One method for reducing the need for cleaning or even eliminate it is through industrial vibrators designed for bin and chute applications. Electric vibrators are generally the most efficient, delivering the longest life, low maintenance and low noise. The initial cost for an electric vibrator is higher than for pneumatic designs, but the operating cost is lower. Turbine vibrators are the most efficient and quietest of the pneumatic designs, making them well suited to applications in which low noise, high efficiency and low initial cost are desired.

Air cannons are another approach to maintaining good material flow, particularly in larger vessels. In the mining industry, air cannons are frequently specified to eliminate build-ups in hoppers, storage vessels, transfer chutes, bins and other production bottlenecks. They can also be found in mineral processing plants where metals are extracted using processes creating slurries and other wet, tacky tailings. The timed discharge of a directed air blast can prevent accumulation or blockages that reduce process efficiency and raise maintenance expenses. In underground mines with potentially explosive dust, manual firing of cannons without the use of electrical solenoids is an option.

The two basic components of an air cannon are a fast-acting, high-flow valve and a pressure vessel (tank). The device performs work when compressed air (or some other inert gas) in the tank is suddenly released by the valve and directed through a nozzle, which is strategically positioned in the tower, duct, chute or other location. Often installed in a series and precisely sequenced for maximum effect, the network can be timed to best suit individual process conditions or material characteristics.

“There are a number of approaches that can help resolve those problems caused by material accumulations and blockages before they turn into expensive downtime, lost material and safety hazards,” Pronschinske concluded.