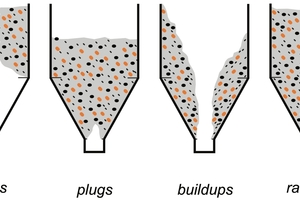

How to prevent material clogging

Hoppers and silos for mines and quarries extracting raw material are designed for the needs and environment at the time of construction, but production demands and shifts in climate are changing the dynamic. Modest changes in moisture content can cause adhesion to hopper and silo walls. Low temperatures and changes in atmospheric pressure – especially if the silo is stagnant for long periods – can contribute to flow changes. This article explains how to prevent blockages caused by material.

Air cannons are engineered to safely clear and prevent clogging, promote material flow and avoid costly downtime. To know if...