Recycling of fine-grained construction waste

In 2016, the construction industry used 563 mill. t mineral resources. As a result of the demolition of buildings, around 54 mill. t building rubble is produced. During the processing of this rubble with mechanical methods, around 5 mill. t fine fractions smaller than 2 mm are formed. On account of its heterogeneous composition, this volume of materials is almost always landfilled. This process continues to this day. At the same time, resources from domestic quarries have already been almost exhausted and new extraction sites are scarce.

So as not to completely exhaust the finite deposits of raw materials for construction and to make low-cost materials reliably available, in 2016 the Fraunhofer Institutes for Building Physics (IBP), for Material Flow and Logistics (IML), for Optronics, System Technologies and Image Exploitation (IOSB) and for Environmental, Safety, and Energy Technology (UMSICHT) joined forces to analyse and develop new recycling possibilities for construction rubble in the scope of the “BauCycle” project funded internally by Fraunhofer. The results of the project are to be further developed in follow-on projects to demonstrate concrete strategies for a more sustainable construction sector. Here, the research consortium maintains intensive exchange with the Fraunhofer Building Innovation Alliance, which has made it its aim to inform industry and politics about current trends, the resulting requirements and potential solutions for the construction sector. As in the scope of the project, new forward-looking construction materials were developed from recyclates, “BauCycle” offers not only solutions for the “Resource Efficiency” area but for the “Advanced Materials” area of the Alliance at the same time.

Processing and recycling construction rubble

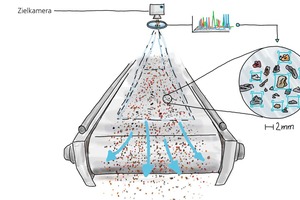

First, the project team addressed the development of a process for the optical sorting of construction rubble to selectively separate its main constituents concrete, clay brick, limestone and gypsum from each other. Here, a hyperspectral camera was used to analyse the mineral composition of the construction rubble spectroscopically according to chemical criteria and the composition was then used as a sorting parameter. In the different material groups, a purity of around 99.5 % could be obtained. Parallel to this, the scientists worked on construction product samples and formulations, for example for aerated concrete blocks, in which 30 mass% of the sand as a primary resource could be substituted with the recovered, fine-grained construction rubble material.

The team also produced cement-free construction materials on the basis of construction rubble. They developed an acoustic plaster with 60 mass% recyclate content for interior applications, which exhibits a comparable acoustic quality to that of products already available on the market. The developed product samples underwent an initial sustainability assessment and were on display in January, at the Bau 2019 trade fair in Munich. In the last step of the project, the group of researchers fabricated a demonstrator for a market platform through which the construction rubble fractions can be traded and on which different sources and sinks of primary and secondary resources are intelligently networked.

In recognition of their successful work, the project participants were awarded first prize in the “Research “category for the “BauCycle” project by the German Sustainable Building Council at its Annual Meeting on 25 June 2019. Depending on the category and subject area, the award winners receive coaching by qualified experts from the DGNB network as well as a presence in the DGNB Living Showroom in Stuttgart.

Work to continue in follow-on projects

With the conclusion of the project, this subject has not been exhausted by a long way. In future, too, on the basis of the findings of the “BauCycle” project, the scientists will work on the functionalization of cement-free construction materials and increasing the content of recyclate in the production of aerated concrete and innovative construction products in future, too. Moreover, they are continuing to research the production of cement-free and corrosion-resistant construction products. In addition, other potential recycling routes have to be found for the fine fractions of the construction rubble fine. The researchers want to further optimize the sensor-based sorting systems to, for example, successfully realize inspection applications aside from the construction rubble. The focus is on the testing, utilization and fusion of problem-specific spectral ranges as well as the application of so-called “hyperspectral imaging” for material-identifying image processing.

Moreover the Fraunhofer employees are using the methods developed for simulation of volatile material stream networks. The basics of the market platform are to offer customers from different branches in forwards- and backwards-directed value creation chains tailored solutions for increasing efficiency in logistics for a genuine circular economy.

The project was funded as part of the Fraunhofer-internal programme for market-oriented applied research “MAVO”.

//www.baucycle.de" target="_blank" >www.baucycle.de:www.baucycle.de