Recycling today for a better tomorrow

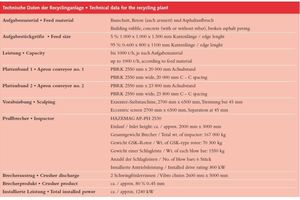

The HAZEMAG crusher is powered by an 800 kW slip ring motor. Two HAZEMAG Apron Feeders are used to transport the rubble, the first draws material from the storage bin, and the second which the speed can be controlled, separates the mass flow, so that the rubble is evenly distributed across the full width of the feeder. The material is then fed onto an eccentric pre-separator screen which sieves out any fine material prior to the HAZEMAG crusher.

The crushed material is then conveyed away with two vibrating feeders and a belt conveyor. A magnetic belt separator for the separation of metal components is also installed at this point in the system. The recycling plant was supplied with complete steel construction and electrical switchgear from HAZEMAG.

Due to the quality and robustness of the HAZEMAG impact crusher, the wear rate on the internal components is minimal, and maintenance work is only necessary for the replacement of worn wear parts which has cost optimization as a major feature.

$(LEhttp://