Relying on regularity

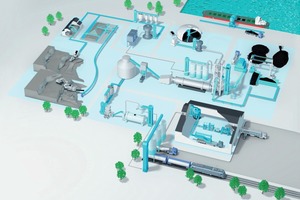

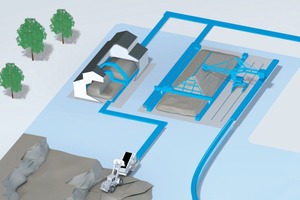

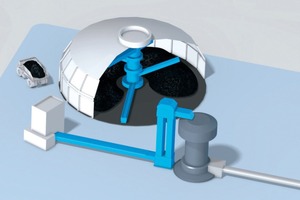

For almost 80 years, BEUMER has been developing tailor-made system solutions in conveying technology for the stone and quarry industry, power plant industry, mining (ores and coal) as well as the logistics industry (harbours and transshipment terminals). Furthermore, the specialists have comprehensive expertise in engineering of blending beds and stockpiles. Through structural analysis of the associated storage depots and calculation of dimensions, BEUMER is able to provide a design. The blending beds are customized according to their requirements. BEUMER proposes either longitudinal or circular stockpile designs. The recommended design shape results from the spatial conditions and the amount of the material to be stored. Depending on the field of application, BEUMER designed blending beds can be used at extreme ambient temperatures, for very high entry conveying capacities, as well as for the highest degree of homogenization required. Additionally, BEUMER provides material-specific detailed solutions with robust and low-wear equipment. The environmental impacts are also very low as minimal noise and dust occurs during operation. Blending beds can be set up both outdoors and indoors.

Compiled and extracted in layers

The stacker and the bridge scraper are the basis for a blending bed. If they are perfectly designed, the user will obtain an optimum blending effect. BEUMER offers stackers that stack the bulk material efficiently and effectively. In the end, the stockpile has been raised so reliably that its cross-section shows as many layers of equal material as possible. The stackers can be of fixed or mobile types, depending on the requirement. In case of circular stockpiles the stackers are mounted onto a column and with a longitudinal blending bed, they are mounted on rails. The stackers are designed as fixed, raisable and pivotable booms with conveying capacities of up to 4000 tons per hour. The choice of the right system depends on different factors, as for example, the shape and size of the stockpile, the material, the throughput and the desired mobility.

Lastly, the bridge scraper homogenizes the material. It has a mobile rake on each side. The material is removed in layers by stroking the face of the stockpile with the rake. The scraper blades move the bulk material towards the belt conveyor which runs parallel to the stockpile. BEUMER bridge scrapers are not only robust, but they also transport the bulk material so that the product is handled gently. This makes them suitable for a variety of bulk materials. Their continuous and comparably simple working motions allow for a fully automated operation and ensure a constant and steady flow of the bulk material.

Stand: B2.413

$(LEhttp://