SKF GmbH

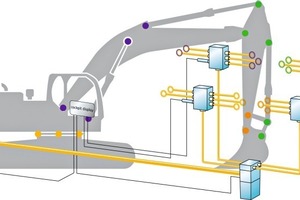

SKF will be present at bauma 2013, with a wide range of lubrication solutions for the construction machinery industry: from application-specific lubricating oils and greases to automatic lubrication systems.

The extensive know-how of SKF in bearings and motion technology forms the basis for its highly efficient lubrication systems. Having acquired the American company Lincoln Industrial, a leading supplier of lubrication systems, tools and equipment, SKF now offers one of the biggest lines of products and services on the market; tailor-made solutions for customers in a variety of industries and for a wide range of tasks.

With this broad foundation, SKF offers solutions for manually operated grease guns, lubricating oils and greases of all kinds, as well as a complete range of automatic lubrication systems. It even has solutions for special applications like hydraulic hammers and teeth in open gears.

In addition to these products, the company can help to reduce the life cycle costs of machinery or equipment and increase productivity. The SKF Life Cycle Management plan for machinery comprises all the necessary services, from specification and design to application. SKF experts not only provide advice on selecting lubricants, they install automatic lubrication systems and provide regular maintenance. SKF offers this technical support, which is precisely tailored to the needs of its customers.

Outside area F7; Stand 709/4