Sand extraction through mobile processing

Summary: A flourishing construction industry without sand is unthinkable. According to OneStone Consulting, around 10 to 15 billion tons of building sands are required worldwide each year [1]. In addition, we need industrial sands, for example for fracking or the glass industry. This corresponds to a per capita sand consumption of about 2 to 8 tons per year, so that a total of 40 to 50 billion tons of sand and gravel must be extracted. This makes sand the second most traded raw material after water [2]. Since the demand for sand is growing faster than suitable sand resources can be found, sand is instead produced from gravel or transported over long distances. This is not environmentally reasonable. RHEWUM has developed a solution to process sand mobile and therefore directly on site.

The raw material

Quartzite sand is mainly used in the construction industry. It consists of silicon dioxide (SiO2). The great hardness of the material (7 ° according to Mohs) is an advantage. The usual grain sizes in the building industry for coarse sand are 0.63 to 2.0 mm, for medium sand 0.2 to 0.63 mm and for fine sand 0.063 to 0.2 mm. Whereby the finest fraction (below 63 µm) must be removed to avoid silicosis (pneumoconiosis), as these fine particles settle in the lung tissue and can lead to chronic inflammation.

The occurrence

In simple terms, sand is produced by the weathering of minerals. However, all rocks weather differently. A sand-lime brick weathers much faster than a hard quartz rock and subsequently rises again in superficial sediment. The proportion of sand here lies at around 10 %, while the proportion of gravel in these sediments amounts to 20 % [1]. Unfortunately, the global demand cannot be covered by the sand deserts of our earth, as so often hoped for. It is too fine-grained and round, so it cannot be used as an aggregate for concrete. Usable sand is mainly found in rivers and on the coasts of emerging countries, where it is often extracted without regulation. For this reason, countries such as Malaysia, Cambodia, Vietnam and Indonesia have generally banned the export of sand.

The demand

In Germany, the construction industry is already warning about a sand shortage. Most buildings are made of concrete, which in turn consists of 60 % sand. Each medium-sized house requires around 200 t of sand and every kilometer of highway requires around 30 000 t. In addition to these applications, the raw material is also used in glass, detergents, microprocessors and many other areas. For this reason, ships transport sand daily to regions that need sand but do not have the necessary resources. For example, Singapore imports around 400 truckloads of sand every day, while Bangalore in India imports 100 trucks a day [3]. Alternatively, sand is also extracted directly from beaches or riverbeds. The long-term consequences for the environment and its population are controversial.

The required particle sizes

Sand for the production of concrete is subject to the relevant standards such as DIN EN 197-1 or DIN 1045-2. Sands usually have a grain size between 0 and 2 mm, while gravel or grit range between 2 and 8 mm. A standard cubic meter of concrete requires about 150 l of water, 300 kg of cement, 630 kg of sand, 580 kg of fine gravel and 700 kg of medium gravel. Correspondingly, just over 30 % of the total quantity of concrete is building sand [1].

The production of sands

The extraction of the resource sand is usually handled stationary. For this purpose, the sand is washed and classified into appropriate grain classes. If the resource sand is not available, gravel can be crushed and then classified.

The mobile screening of naturally moist sands

While mobile crushing and screening plants for processing coarser classifications over 2 mm have already proven their worth in road construction, this innovative concept has not yet been able to establish itself for finer separations. One problem in fine classification is the design of the screening machines used. The screening machines normally used, with a vibrating housing and amplitudes and frequencies unsuitable for fine screening, do not achieve the required screening qualities. Accordingly, the industry has not pursued this concept further, although it would offer massive advantages for the operator of such a plant. However, if a directly excited screening machine is placed on a conventional equipment carrier, fine sands can also be produced directly on site in the quarry. Without having to transport them over long distances before processing.

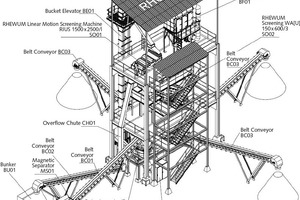

The semi-mobile production of moist sands

If no sand is available, but gravel is, it can be used as a raw material for semi-stationary processing. Semi-stationary means that the required sand is produced in a light steel construction. An advantageous arrangement of the required machines allows this design. While the supposedly heavy crusher is arranged near the ground, directly excited static screening machines are used for the subsequent fine screening. This relieves the steel construction considerably and the plant can also be easily moved at a later date. The feed material, as well as the fractions produced, are set up directly in the quarry in the first step by means of a wheel loader and only require a floor space of 30 by 20 m. Only two employees are required to operate such a plant. The example configuration shown in Figure 4 produces around 35 t/h of saleable sands.

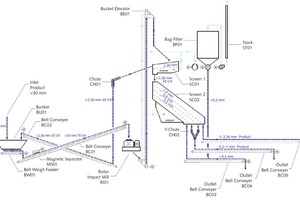

The flowsheet (Fig. 5) to the sand processing plant from Figure 4 contains only the essentials for producing sand from gravel. After feeding, the material flow is taken from a small storage container by means of a weigh feeder and transported to the plant. To protect the mill, larger metal particles are separated along the way. In this configuration, an energetically efficient rotor impact mill produces the required fractions, which are transported via a bucket elevator to a coarse screen. While the oversized particles are returned to the feed, the usable fraction leaves the coarse screen and is then screened into fractions ready for sale on a directly excited magnetic screening machine. These fractions are transported by belts to small stockpiles for sale. Both feeding and removal are carried out flexibly by means of wheel loaders.

Thanks to the use of energy efficient machines, the sand processing plant can be operated energy self-sufficiently with the help of a power generator – an advantage in emerging countries with insecure power supply and in remote areas.

Summary

The German saying “Like sand on the beach” is no longer true in many areas due to the immense consumption of sand. In order to bring the sand to the consumers, it is possible to transport the sand from sandier areas to sandier areas. In many places around the globe this is already happening today. It is doubtful whether this approach will leave a positive ecological footprint. It seems to make more sense to produce the required sand grains from the far more widespread gravel in the vicinity of the customers. In order to secure the necessary investments as far as possible, it makes sense from the operator’s point of view to keep such plants mobile. In this way, sand processing plants can follow either the resources or the customers. Transport costs and negative effects on the environment would thus be minimized.

Literature

[1] Harder, Joachim: Rohstoff Sand – Eine Mangelware. AT MINERAL PROCESSING 01-02/2020, S. 48-60

[2] Ritter, Johannes: Warum Diebe einen Strand klauen. F.A.Z., 07.05.2019

[3] Charton, Cordelia u. Janczura, Sarah: Sandverbrauch führt zum Raubbau an der Natur. www.ingenieur.de, 03.03.2020

[4] Schütz, Sigurd: Erzeugung siebreiner Fraktionen bei naturfeuchten Körnungen mineralischer Rohstoffe. AT AufbereitungsTechnik, 07/2006, S. 28-34

[5] Planungsunterlagen der RHEWUM GmbH

Author: Dipl.-Ing. Sigurd Schuetz

RHEWUM GmbH, Remscheid/Germany

www.rhewum.com

Dipl.-Ing. Sigurd Schuetz studied process engineering at Cologne University of Applied Sciences. He then worked in mechanical process engineering and mineral processing for globally operating companies. Here the focus was on development, design and sale of comminution and sizing equipment. Dipl.-Ing. Sigurd Schuetz has been working at RHEWUM GmbH since 2001 and widened his technical expertise in screening and sorting technologies. After being sales manager, he was appointed managing director of RHEWUM GmbH in April 2007.