Sandvik presents AutoMine® Access API specification

Patrick Murphy, President Rock Drills & Technologies, Sandvik Mining and Rock Technology said: “While we think customers will achieve the highest performance with Sandvik equipment, we recognize the need to unlock automation’s full potential for all equipment regardless of manufacturer. Customers with mixed fleets will now have the full power of AutoMine® behind them.”

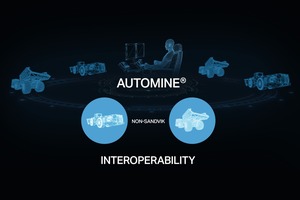

The AutoMine® Access API is a standard set of pre-defined interfaces for connecting third-party loaders and trucks to AutoMine®. This means a mixed fleet of underground loaders and trucks can now be managed and controlled with one seamless system. An API (Application Programming Interface) is a set of functions and procedures that allows the creation of applications that access the features or data of an operating system, application, or other service. The third-party equipment is also required to meet the AutoMine® safety standards.

The AutoMine® Access API is another step in Sandvik’s journey to drive a digital ecosystem that makes mining smarter, safer and more productive. In 2018, Sandvik Mining and Rock Technology released its Interoperability Policy outlining how Sandvik systems can communicate within a digital ecosystem including data accessibility, fleet data compatibility, data rights and control, and data privacy.

The momentum continued in 2019 with the acquisition of Newtrax, a leader in wireless IoT connectivity for underground hard rock mining, and the announcement that My Sandvik, Sandvik’s telemetry solution for machine health and productivity data, would also be available for non-Sandvik equipment. “Thousands of pieces of equipment around the world are connected to our digital technology,” said Murphy. “ As more customers embark on their digital journeys, interoperability will be a requirement. We are proud to drive digitalization further in the mining industry.”