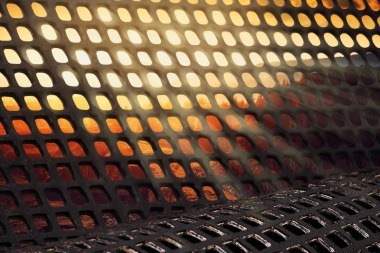

Screen media combining durability and high accuracy

Tailor made for the required specification, there are three different types of media within the WX-Range available for Sandvik mobile screening and scalping equipment. These cover a wide range of applications from fine to medium, to coarse, and more difficult applications; the WX6000, WX6500 and WX7000 respectively. All are dependable, flexible screening solutions with a low environmental impact. They offer 50 % less noise compared to wire mesh.

Sandvik WX6500 screen media is the general all-round media. It has the same accuracy as wire mesh at 2 – 32 mm separations and offers all the benefits of rubber media. It basically does the same job as wire mesh but with a much longer lifetime; tests have proven it lasts up to 10 times longer.

It also offers the following benefits:

Fewer media changes

With up to ten times the durability of wire mesh, Sandvik WX6500 gets changed significantly less often, so customers experience far less screen downtime

High sizing accuracy: 2 – 32 mm

Sandvik WX6500 has the same accuracy as wire mesh. For the very first time, customers can choose a rubber media for fine screening

Less blinding and pegging

The thinness and flexibility of the reinforced rubber prevents the blinding and pegging associated with wire mesh. Sandvik WX6500 gets customers the end product they want – the first time through the screen

Higher uptime

Due to the anti-blinding and less pegging, customers spend less time on media inspections, troubleshooting, fitting replacements and therefore benefit from more uptime.

WX6000 and WX7000 offer similar benefits to the WX6500 in terms of durability, less blinding and pegging, and higher uptime. Key differences are the types of applications they will be used in:

WX6000 is ideal for fine to medium-coarse screening with a larger feed size of up to 150 mm

WX7000 is suitable for intermediate and final stage screening where more accurate screening is required, maximum feed lump size of up to 30 mm.

The WX-Range is already in use at the Pony Pass quarry in the Falkland Islands. Due to the remote location and tough operating conditions, Pony Pass quarry were looking for equipment that was reliable and built to last, down to the last detail. This includes the type of media fitted to their two Sandvik QA451 doublescreen units which are a key component in their crushing and screening operation.

Marc Short, Quarry Manager, comments: “Due to our location, we had to source equipment that wouldn’t need replacement parts and screen media on a frequent basis. We decided to invest in the WX-Range of screen media due to its reliability. We have the WX6000 media fitted on the top deck, WX6500 on the middle and WX7000 on the bottom deck of our two QA451 3-deck doublescreens. We are satisfied with the product and have seen hardly any wear after a year’s operation. They fit the job perfectly.”

Sandvik screens offer superior wear protection to meet high demands with regards to accuracy, efficient production, a safe and cleaner working environment and uptime. The unique Sandvik screen media offering is available in almost any size, thickness, and aperture shape, with patterns tailored to customers’ needs. The WX-Range is already available as an aftermarket offering for applicable products within our Wheeled offering.