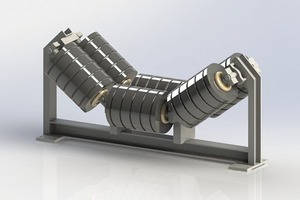

Support and tensioning rollers play an essential part in belt conveyors

The primary purposes of the support and tensioning rollers in a belt conveyor are to shape the belt, serve as a support element for the transported material, and reduce resistance to movement. When the material is transported with minimal friction, the overall energy required for transportation is reduced, thereby also reducing the operating costs. In a mining environment, belt conveyor rollers are exposed to harsh operating conditions and environments: heavy loads, vibration and shaft deflection stresses, high rotating speeds, increasing load from external contamination, and demanding weather conditions such as high humidity, rain or snow and extreme temperature variation.

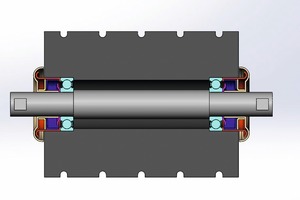

Some of the most important components in support and tensioning rollers in belt conveyors are roller bearings. Even if the bearings used in the belt conveyor rollers are properly designed, sealed and permanently lubricated, they are significantly influenced by the above-mentioned factors. The tremendous amount of dirt in the mining environment creates conditions for impurities to infiltrate the bearing point and can lead to premature equipment failure. This not only shortens the service life of the bearing, but it also has negative consequences for the performance and reliability of the other components of the conveyor system.

After extensive analyses, NKE has developed single-row deep groove ball bearings especially for belt conveyor rollers that operate in harsh conditions. With a completely re-engineered design, it has succeeded in making targeted improvements that optimize performance capability and service life compared with standard bearings. These bearings have a special cage construction of low-friction synthetic material, improved raceway geometry, adjusted radial internal clearance, special low friction seals and a selected lubricant for use in a broad operating temperature range.

The new design from NKE is able to sustain operating demands to which conveyor rollers are exposed even where conventional bearings fail. When contaminants infiltrate the interior of the bearing, standard bearings often suffer from a sudden, uncontrolled rise in temperature. The increased temperature impairs the positive lubricant properties, destroys the steel cages and ultimately causes the bearing to seize up. When bearings seize, they in turn block the rollers, the belt conveyor is damaged, and the risk of fire increases significantly.

Despite relatively high contamination levels, NKE roller bearings for belt conveyor rollers maintain their function even under heavy loads and without increased frictional torque. The new bearing concept from NKE, designed especially to withstand the requirements of belt conveyor rollers, offers a range of advantages: it reduces the risk of fire, prolongs the service life of the roller bearings in the harshest conditions, reduces energy consumption, increases the conveyor system’s reliability and lowers overall operating costs.

“NKE has tremendous expertise in mining applications,” says Michael Rössl, Applications Engineer with NKE in Steyr. “This is an extremely complex engineering achievement in response to the wish expressed by many customers for improving the functional capability of belt conveyors. Our new roller bearing system will help to substantially lower outage times in material transportation.” The new bearing design ensures frictionless rolling processes, thus helping to minimize friction throughout the entire system, and makes it possible to run the transport system more cost-efficiently and more reliably. “In order to achieve the best possible results, measures to prevent particulate contaminants from penetrating the bearing and the bearing interior as completely as possible must begin with the plant developer or the plant operator installing external sealing systems,” adds Michael Rössl.