TK-D drum dryer/cooler: Energy saving and low product temperature

thanks to maximized efficiency

Around the world,Allgaier’s System Mozer drum dryers/coolers are synonymous with high-quality, high-capacity and efficient drying and cooling systems. They are used especially for processing free-flowing bulk solids, but also for sticky, lumpy or highly abrasive materials. The always individual and application-driven design and fabrication of the drums as well as special models enable a very wide range of applications for throughput rates from 1 t/h to over 350 t/h, as well as process steps combined with drying.

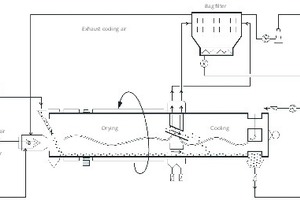

Combined drying and cooling with the TK-D

The TK-D drum dryer/cooler is an advanced development of Allgaier’s successful TK and TK+ series of dryers/coolers, which can cool the product to around 50 °C. In some applications, like, for example, for foundry sands or in the production of ready-mix products like construction adhesives, however, very low temperatures close to ambient or cooling air temperatures are required for the dry materials supplied. This is where the developers of the new TK-D came in: The cooling of the solid to especially low temperatures is enabled by a single-shell design in combination with separate drying and cooling zones in the drum. Thanks to the use of previously cooled air instead of ambient air, for speciality products, the solids can even be cooled to temperatures down to 10 °C.

With the two-part configuration of the central chamber with a partitioning wall, for feed of the product from the drying to the cooling zone, streams of exhaust air are separately discharged from the drying and the cooling zone and dedusted. While the moisture-laden exhaust air from the dryer is dedusted and released into the atmosphere, the warm but dry and dedusted cooler exhaust air can be recirculated into the process as preheated drying air, leading to heat recovery from the dry and warm solid. Heat recovery in the drying process coupled with evaporative cooling, i.e. re-evaporation of the residual moisture from the solid in the cooling process, leads to an improvement in efficiency and an up to 20-% saving in the energy required.

In addition, the separate feed and discharge of the air streams allow different process configurations between the solid and air.

Parallel- or counter-flow drying, which can be combined independently of each other with

Parallel- or counter-flow cooling

The enabled counter-flow of drying air and solids stream is particularly suitable for very efficient high-temperature treatment and calcination of the solids with cooling immediately after. The drying or heating zone can be configured and optimized completely independently from the cooling zone.

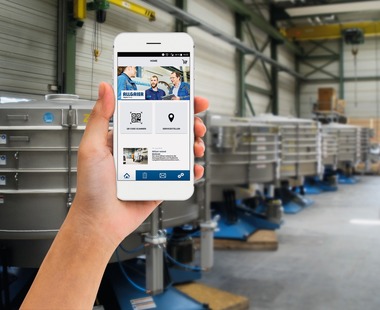

Maintenance friendly

Thanks to its single-shell design, the new TK-D is very maintenance-friendly. The drums usually have a large diameter, as a result of which the complete length of the drum can be very easily accessed to conduct inspection and maintenance work. Moreover, for inspection and maintenance, the TK-D has large-size openings, referred to as manholes, both in the drum body itself and on the dryer housing. These are located in easily and safely accessible positions. Accordingly, areas of the drum shell attacked by wear can be quickly identified and easily repaired or renewed. Allgaier offers the necessary service with operatives working around the world and dedicated supervising.

Case study

The TK-D has already proven effective in a range of industrial applications. Its functionality has therefore been reliably demonstrated. One typical application is at a dry construction materials plant in Latin America, where natural sand in the size 0 – 3 mm with an initial moisture content of around 5 % is dried to a residual moisture of less than 0.4 %. The following cooling is performed to temperatures between 40 and 50 °C, depending on current ambient air temperature between 20 and °C. As these low dry product temperatures required by the customer, even with high ambient temperatures, cannot be achieved with multi-shell drying/cooling drums, these requirements were the main reason prompting the customer’s decision to buy a TK-D.

With the TK-D drum dryer/cooler, Allgaier Process Technology offers an efficient, versatile, robust and compact drying-cooling drum, which thanks to its single-shell design is particularly maintenance-friendly and cost-efficient. The TK-D impresses with high quality and drying to low temperatures, and can be used in a wide range of applications, especially, in the minerals, construction materials and raw materials industry.