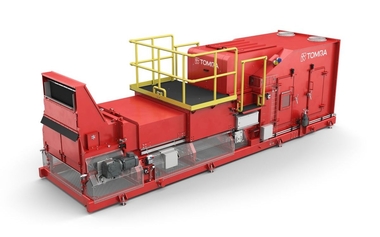

TOMRA introduces virtual demonstration and test sessions

TOMRA’s temporary Virtual Demonstration and Test Solution will enable mining companies to test the sorting solutions on their samples without leaving their office. They will just need to book a session with their TOMRA Sales representative and ship a sample of their minerals to the Test Center, which will conduct the test. Once it is completed, they will receive a video of their material being sorted and discuss the results with a TOMRA’s sales person and the Test Center’s experts via video call. With their support, they will be able to make a decision on the following steps and take the project forward without delay. Albert du Preez, SVP and Head of TOMRA Sorting Mining, explains: “The visit to one of our Test Centers can be an important step, as it enables them to work out with our teams the best combination of technologies and develop the flow sheet for their ore sorting plant.”

The opportunity for the customer to see first-hand the equipment at work on their sample and discuss the options with TOMRA’s team provides important added value. This was the experience of John Armstrong, VP Mineral Resources at Lucara Diamonds, who visited the Test Center in Wedel when researching a solution for the mine in Karowe, Botswana: “We gained a lot of confidence in the people at TOMRA, in the technology that they were presenting to us, and the possible solution that it provided to the Karowe mine. […] We could also see that they had already gone down the road of the next step in XRT technology, so they were not just focused on one particular module to present to us, but they were working on different modules. That helped alleviate some of our concerns about the robustness of the platform and the technology itself, which ultimately led us to use TOMRA as the solution.” Lucara has since gone on to recover some of the largest diamonds in history with the TOMRA X-Ray Transmission system installed as a result of this visit to the Test Center.

The development of this Virtual and Demonstration and Test Solution is the latest action in TOMRA Mining’s plan to ensure it provides customers all the support they need in the current situation. It has increased stocks of critical components to ensure its ability to fulfill current and future orders, and to ensure the supply of spare parts without disruption. The company is leveraging digital technology not only to take the expertise of its Test Centers to customers, but also by using its remote service and training tools to support their equipment while respecting social distancing safety measures.