Targeted dust control for low-turbulence applications

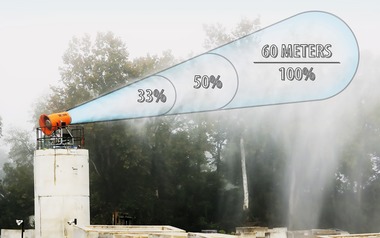

Dust Control Technology has engineered a smaller version of its low-turbulence atomized mist unit for applications that require precision particle control without the disturbance of a fan-driven design. Developed for applications such as conveyor unloading points and other limited-space dust-producing areas, the DustBoss® DB-M Mini is built to provide effective suppression without material disruption or saturation (Fig. 1). Generating a cascading mist of atomized droplets averaging 50 -200 µm in size, the unit has a throw of about 10 feet (3.04 m) under calm conditions. The result is effective fugitive particle management at the source of the problem, with little pooling or runoff.

“We’ve found suppression is best achieved by controlling dust at the source whenever possible,” said Dust Control Specialist, Carl Harr, from Dust Control Technology (DCT). “We designed this compact version of the DB-M to fit into smaller spaces to directly address those specific problem areas. It’s well suited to applications involving very fine dust particles, such as slag dust or fly ash,” he added.

The standard boom length is 2 feet, but can be specified anywhere from 1 to15 feet (0.3 to 4.57 m). It is fitted at the end with a misting head featuring 9 atomizing nozzles. With a minimum required pressure of just 10 psi (0.69 bar) and a maximum of 100 psi (6.89 bar), water is fed through a standard 3/4“ swivel hose coupling or an optional 1-1/2“ NPT connection. The water travels through an in-line 75 mesh (200 µm) filter, up the boom and to the head, where the atomizing nozzles fracture the flow into millions of droplets, which are distributed evenly across the target area (Fig. 2).

According to Harr, every operation is unique, which may require a high level of customization. “Dust particles vary widely in both composition and size,” he said. “These differences require droplet sizes that match the particle sizes in order to be most effective, and in some cases chemical treatments are needed, as well.”

Along with the customizable boom length, proprietary Variable Particle Sizing (VPS) Technology allows specialized nozzles to be added, removed or replaced on the head in order to customize droplet sizes for optimum suppression. If using potable water, nozzles need only be inspected once per year.

An optional dosing pump can be attached for accurate metering of odor control additives, surfactants to improve binding to particles, or tackifying agents to help seal ground-level dust and prevent it from becoming airborne. The unit runs a water pressure alone, requiring no electrical hookup.

//www.dustboss.com" target="_blank" >www.dustboss.com:www.dustboss.com