The Multifunctional Mixer for the Laboratory and Production

Until now dry mixes have been made in a mixer, plastic compounds in a kneader and suspensions in a dispersing unit. These are normally very different machines, because a standard mixer is unable to knead and a kneader can neither mix nor disperse.

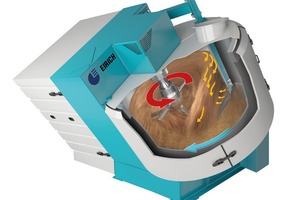

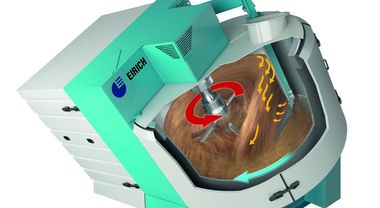

That’s not the case with the EIRICH mixer that is in successful use across many industries. The unique working principle of this unit is characterized by a rotating pan for transporting the mix and a tool running at variable speed – slow to fast. Because the transport of the mix and the mixing process are separate, this mixing tool can run very fast if necessary, with tool speeds up to more than 30 m/s. This allows the energy input into the mix to be adjusted to the specific mix and is why these mixers can mix, granulate, coat, knead and disperse.

At Powtech EIRICH will be demonstrating the process engineering opportunities offered by this mixing system. It will also present a revamped series of laboratory mixers with capacities of 1 to 10 liters.

The mixers are used in a large number of recycling applications and for the treatment of contaminated soil. Over the last few years the fertilizer industry has also shown increasing interest in having mixing, granulation and coating performed in a single machine – now possible with the multifunctional EIRICH mixer and already the norm in many plants around the world.

The multifunctional mixers allow even difficult to highly viscous products to be processed, enabling them to be used as an alternative to Z kneaders. Process times can thus often be cut from several hours to as little as 10 minutes or less, and the compounds prove to be more homogeneous than those prepared with the kneader.

For users who have to produce products with different consistencies, this technology simplifies the production equipment required – inventory, feeding and weighing only need to be performed once. What is more, it is possible for several production stages performed one after the other in various units to be carried out in one and the same machine.

In the Test Center facilities available at all the company’s sites, tests are performed with the customer’s raw materials in order to determine the optimum machine configuration. The resulting system concepts help prospective customers when they need to ensure that production equipment meets their future requirements.

Hall 4A / 409

$(LEhttp://