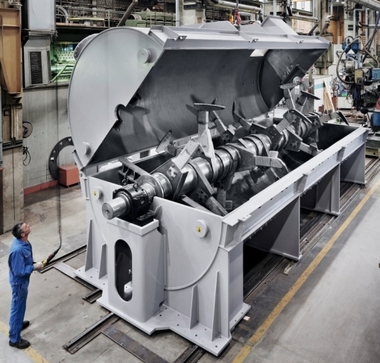

The biggest mixer ever built by Lödige

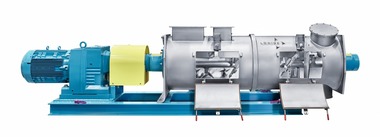

Lödige Mixers are in use all over the world but the machine which left the head office in Paderborn/Germany on February, the 4th 2015 is something special for this company with a long tradition: having a total length of 11 m and a weight of approx. 60 tons, this machine is the biggest that Lödige has ever built in more than 75 years history. The intensive mixer of type KM 57.000 will operate in a steelworks in India (Fig.).

This mixer will be used for the mixing and granulation of sinter material which is necessary for the production of raw iron in blast furnaces. This process step will improve the homogeneity of sinter raw mixes which are composed of coarse and fine iron ore, limestone and further materials. The mixer is designed to achieve up to 1400 tons of material per hour. The retention time of the product in the drum is 90 seconds. The machine runs in continuous operation day and night as fresh supply for the blast furnace must be ensured at any time. Having a diameter of 3 m and a length of 8 m, the split design of the mixing drum enables in this way a rapid and easy performance of maintenance works to meet this heavy duty application. The maximum standstill time is thus reduced to only one to two weeks a year.

//www.loedige.de" target="_blank" >www.loedige.de:www.loedige.de