The new impact crusher from Keestrack

Keestrack, one of the world‘s leading manufacturers of heavy-duty screening, impact crushing and jaw crushing machines, has extended its product range to include a compact model. In this 26 t impact crusher, the Belgian company has succeeded in making the robust technology of its large-scale impact crushers available to users of compact machines.

The development of the Destroyer 1011 also enabled Oppermann & Fuss to incorporate its many years of experience in the marketing and rental of small recycling machines. Consistent attention was devoted to eliminating the weaknesses of the compact systems previously available.

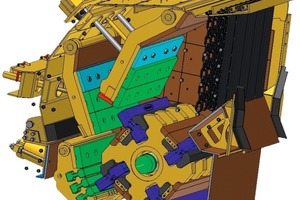

Particular attention was focussed, for example, on rotor and crusher weight. The weight of the crusher, and of the rotor, in particular, is extremely high compared to that of the machine as a whole, and is almost twice as heavy as in comparable machine types. With a rotor weight of 3200 kg and an overall crusher weight of 8500 kg, Keestrack here sets totally new standards for oscillating mass and stability. The high oscillating mass of the rotor makes it possible to achieve superior crushing results with a smaller motor unit (Fig. 1). The Deutz diesel engine installed delivers over 1000 Nm at 1800 rpm. Professional users will equally appreciate the two independently adjustable impact disks. The crusher chamber can be quickly and easily equipped with an optional milling bed for special tasks requiring a high degree of comminution.

The asymmetrical design of the vibro-feeder, with its separate feed trough, achieves more effective fluidisation of the feed material and improved extraction of fines fractions prior to crushing (Fig. 2).

In line with Keestrack‘s normal practice, this machine, too, consistently conforms to the transport dimensions customary in Germany. Immediate transportation without the need for any special approvals is possible at any time, thanks to the machine‘s transport height of 3.10 m, transport width of 2.55 m and overall length of only 9.5 m. This also applies with the final-screening and oversize-particle return system installed, since length then increases only to 12.50 m, and total weight does not exceed 30 t. Note, in particular, that the screen frame and the oversize-particle return belt do not need to be removed for transportation, but can, instead, remain fixed to the machine in their working positions.

As in all Keestrack machines, development of the Destroyer 1011 was also careful to ensure the use of standardised components. The final-screening unit, for example, is of identical size to the screen frame of the Keestrack Combo high-performance heavy-duty screening system. Like all Keestrack machines, the Destroyer 1011 has a powder-coating finish.