Value added through washing plant in County Tipperary

A new CDE washing plant installed at Seamus Ryan Sand & Gravel in County Tipperary has increased the value of the fi nal products by 50 % since installation. The quarry is located outside Toomyvara – a small village on the N7 between Roscrea and Nenagh – and has been in operation since 1999. Up until the recent installation of the CDE plant, the company was dry screening all

25 mm material at the site. CDE’s experience of working with diffi cult materials and successfully

adding value was key to their selection as the supplier for Seamus Ryan’s new washing plant. The product output from this site was being sold by the company for further processing in order to maximise its commercial value.

1. Project Outline

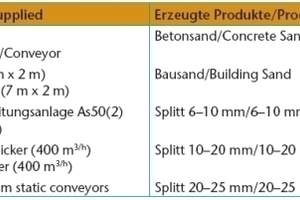

The plant installed by CDE has a capacity of 300 t/h and processes –25 mm material (Fig. 1). The equipment suppliedby CDE includes a 55 t feed hopper with combined 25 m inclined conveyor. This conveyor feeds a large triple deck rinsing screen from CDE’s ProGrade range. The product output from this screen is 3 sizes of chips: 6-10 mm, 10-20 mm and +20 mm which are discharged into concrete bays. The –6 mm material is sent to one of CDE’s EvoWash dual sand plants and produces concrete sand and building sand. The sand plant removes all the –63 micron material and this is sent to the AquaCycle Thickener along with the waste water. The sludge from the thickener

tank is then pumped to ponds, while the clean water is recycled back to the washing plant, significantly reducing the requirement for fresh water to feed the system.

2. The washing process

From the conveyor, the -25 mm feed material is transferred to the fi rst stage of the washing process. This stage involves a large triple deck rinsing screen from CDE’s ProGrade range. This R3M140 (7 m x 2 m) screen washes and sizes the products into 20 mm, 10 mm and 6 mm chips, which are discharged into concrete bays. The –6 mm material is then sent to a CDE EvoWash sand

plant. The sand washing phase of Seamus Ryan’s plant includes a dual sands plant (Fig. 2), producing both concrete sand and buildingsand. The A series plant, has a split screen, dual cyclones and includes a 10/8 Warman pump.

3. Reducing environmental impact

The –63 micron material and waste water from the washing process are sent from the EvoWash sand plant to the water treatment phase of the plant. This involves an AquaCycle T08 high grate thickener, which has a diameter of 8 m and can deal with 400 m3 of water per hour. This water treatment stage also includes afully automated polyelectrolyte dosing station. As the waste material enters the tank it is mixed with a small amount of fl occulent. This forces all the silts and clays to form a thick sludge that settles to the bottom of the AquaCycle tank. A set of rakes are fi tted to the bottom of the tank and these gently rotate to prevent it from setting and also to move it towards the

discharge point at the bottom of the tank. The rakes also send information concerning the amount of resistance they are encountering back to the PLC control panel, which automatically starts

and stops the main sludge pump as required. The thickened sludge is then pumped to setting ponds on this particular site. Meanwhile, the clean water that has been separated from the sludge overfl ows the top of the thickener tank and is stored in a recycled water tank and then recycled back to the washing plant. The water treatment stage of this plant signifi cantly reduces the environmental impact of the operation by signifi cantly reducing the amount of fresh water required to feed the system.

4. Full project management

CDE were responsible for the delivery of every stage of this new washing plant for Seamus Ryan Sand & Gravel. This began with the design and specifi cation of the equipment in the fi rst instance,

to the manufacture of all the equipment provided. In addition to this CDE were also responsible for the installation and commissioning of the plant. In addition to this, Seamus Ryan has also agreed an ongoing service and maintenance package for the plant. This will involve monthly plant inspections for the first 3 months followed by bi-monthly inspections from one of CDE’s service engineers. This is one of the options offered by CDE as part of their “ServiceMax“ package as explained by After Sales & Service Manager, Raymond Cooke.

Info: www.cdeglobal.com