When to use a mixer and when to use a disk pelletizer or pelletizing drum?

Build-up agglomeration is a well-established method for manufacturing granules or pellets from powdery mineral raw materials. Companies regularly have to ask themselves what the best, easiest and most cost effective way is to manufacture their required products. Mixers, disk pelletizers and pelletizing drums are available for build-up agglomeration. What do these methods have in common, and what sets them apart from each other?

A range of definitions can be found for the terms ’granule’ and ’pellet’. The etymology of both words goes back to Latin, with ’granule’ derived from the word granulum = granule and ’pellet’ originating from the word pila = ball. Granules and pellets can be round, but depending on how they are manufactured they may also have a different shape, such as a cushion shape or cylindrical form, for example wood pellets.

Methods

Thermal and mechanical processes can generally be used to produce granules or pellets. If larger quantities need to be manufactured, the high energy costs associated with thermal granulation are increasingly becoming a problem for many industries. The mechanical processes include press agglomeration, extrusion and build-up agglomeration. Press agglomeration (with roller presses) or extrusion (with perforated roller presses) are tried-and-tested methods, but they do not directly produce a round granule, which is often required. These methods cannot be used with mineral raw materials because of the associated wear. By contrast, build-up agglomeration in disk pelletizers, drums and mixers is low-wear and produces a more or less round granule. In the mixer it is even possible to combine mixing and granulating (and coating) into a single process.

Why choose granulating or pelletizing?

There are many very different reasons for producing granules or pellets from powders, and these reasons vary from one industry to the next – for example, if a product needs to be dust-free for transport, storage or landfilling, or if its flow properties need to be improved, or if the bulk weight needs to be increased etc. Plus, it is also often important to fix a particular state of mixing in cases where the ingredients have different densities, grain sizes and grain shapes. Metallurgical processes are based in part on gaseous material exchange in bulk fills that allow passage of gas, which is why fine ores are pelletized.

Operating principle of build-up agglomeration

Build-up agglomeration is often a cost-effective alternative to other methods of enlarging grains. The following operating principle is used: Rolling processes are used to transform fine particles into larger particles by triggering the effects of binding forces, e.g. by adding liquids like water or additives.

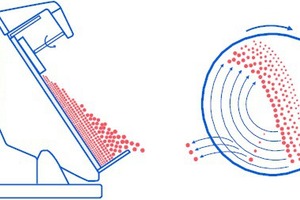

Disk pelletizer

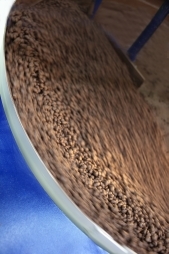

Disk pelletizers are inclined containers with a flattened cylindrical shape that rotate around their axis. The fine material is added and transported via the rotating disk in the direction of rotation until it passes beyond a certain point and falls to the bottom under the effects of gravity, at which point it is then transported in the direction of rotation again. A kidney-shaped area is formed in which the pellets perform a rolling action and grow in size in conjunction with the application of a liquid, which is sprayed via nozzles. Material that adheres to the bottom of the disk is returned back to the process with the aid of a scraper. By adjusting the inclination, rotating speed, ratio of disk diameter to disk edge height and other factors, it is possible to vary the pellet size within wide limits ranging from below 1 mm to 30 mm. As the pellets grow in size, they wander ever closer to the surface and are ultimately transported over the edge of the disk as green pellets A separation effect occurs in the disk, and the ejected pellets have a uniform size. Almost without exception, disk pelletizers always operate continuously.

To ensure that the product has a consistent, uniform character, the pelletizing process needs to be observed at regular intervals. This monitoring is necessary because even minor fluctuations in the amounts of solids or liquids added can alter the process.

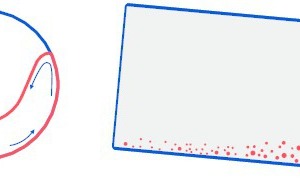

Pelletizing drums

Pelletizing drums are inclined cylindrical containers that rotate around their axis. The material is added and liquid is supplied via nozzles. The material is transported upward under the effects of friction with the wall, and from a certain point it rolls back. The speed of the drum is chosen so that these rolling processes can take place and result in the production of pellets. In comparison to disk pelletizers, drums do not display any size separation effects and thus deliver a broad pellet size distribution. The product is sieved and ground to sort out pellets that are too small or too large, and sometimes quantities are recirculated that are many times the amount originally added. The advantage of this approach over disk pelletizers is that the process never stalls or comes to a standstill even if there are fluctuations in the amounts of solids or liquids added. Drums are used primarily for the preparation of fine ores in systems with high process throughput rates, e.g. iron ore. Pelletizing drums always run in continuous operation.

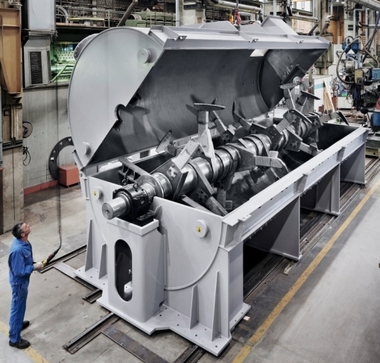

Granulating mixers

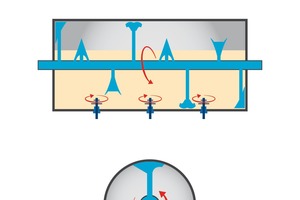

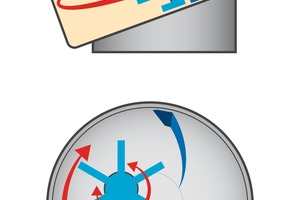

The mixing systems that can be used are pushing mixers and throwing mixers, which are both available in a multitude of designs and variations. Here, we will look in detail at the horizontal mixer, which is also often referred to as a plowshare mixer and can operate both as a pushing mixer and throwing mixer, as well as the compulsory mixer with rotating mixing pan and eccentrically arranged mixing tool, which is often referred to as an Eirich mixer and operates as a throwing mixer.

The horizontal mixer consists of a horizontally arranged cylindrical container, into which a mixing shaft with tools is installed. Depending on the speed of the shaft, the resulting mixing takes place either in a loosened-up product bed or in a mechanically generated fluidized bed. Liquid is added to this fluidized bed, creating the binding forces between the individual particles and leading to the formation of granules. Rapidly rotating choppers are designed to support the mixing and distribution process and prevent the formation of lumps. The size and grain size distribution of the granules can be influenced via binding agents, the dwell time, rotating speed and other machine parameters. The granulating process can run as a batch process or as a continuous process. EIRICH also manufactures this type of mixer in the USA for applications in the food and pharmaceutical sectors, as well as in the chemical industry. The operational limits for hard mixing materials are very tight on account of the friction and wear.

The compulsory mixer with rotating mixing pan and eccentrically arranged mixing tool, which is known as the rotor, consists of a tilted cylindrical container similar to that of a disk pelletizer, albeit with higher walls. The material is moved along by wall friction in the inclined rotating mixing pan. At the highest point, the material is thrown off by a wall scraper and fed to the fast-turning rotor. By intense “mixing” the particles are brought closely together under the addition of water. Once the nuclei of the granules have developed the rotor speed is reduced. The material being mixed rolls over the bottom of the mixing pan and the wall, supported by the slowly rotating mixing tool. This is where the actual build-up agglomeration process then takes place. The grain distribution can be influenced within wide limits via the shape of the mixing tool. Depending on the type of material being processed, granules between 0.2 and 8 mm can be produced. The process can be fully automated and can run without supervision. By virtue of the design of the system, friction and wear are significantly reduced in comparison to a plowshare mixer. The granulating process can run as a batch process or as a continuous process. If the granules are to be coated in the mixer (as is e.g. the case for fertilizers), then a batch process should be chosen.

Combinations of mixer with rotating pan with a disk pelletizer or a pelletizing drum

There can be a range of reasons for choosing combined methods. If the application presents special demands in terms of grain roundness and grain spectrum, then the granules can be manufactured in a combination mixer/disk pelletizer. To do this, fine granules are produced in the mixer and then used as pellet feed. The pre-granulated pellet feed already has the correct moisture and immediately starts rolling into the required shape in the disk pelletizer, thereby significantly accelerating pellet formation. The combination of mixer and disk pelletizer is also recommended for sensitive material systems in which an equilibrium is established in the mixer between particle agglomeration and destruction of the already formed agglomerates (deagglomeration). In addition, a conditioning step can also be incorporated upstream of the pelletizing process, e.g. in the case of pelletizing iron ore, where the fine ore is initially mixed with bentonite. Eirich mixers with a usable capacity of 12 m³ have proved themselves for this purpose. They operate continuously at throughput rates of up to 1500 t/h for periods of several months without any interruptions or need for wear-related repairs.

With the combination of mixer and disk pelletizer, the disadvantages of the two systems cancel each other out (the mixer supplies a wide grain spectrum, the disk pelletizer requires regular monitoring), leaving just the advantages to shine – a narrow grain spectrum and fully automated procedures.

Examples of use in the production of soil improvers and solid fertilizers

1. Inorganic fertilizers and soil improvers

These materials are usually granulated in mixers. In some cases it is possible to also move upstream chemical processes into the mixer, and to design the reaction and granulating steps as a single-pan process. One example is the production of monocalcium phosphate in an Eirich mixer, where calcium carbonate is mixed with phosphoric acid and the reaction product is then granulated in the mixer without the need to transfer it to a different container first. Plants of this type are in operation in Slovenia, Bulgaria and in Peru.

During the production of inorganic solid fertilizer (usually NPK fertilizers) in the mixer, two different methods are generally available: firstly build-up granulation from powdery ingredients, and secondly the production of granules from a moist/wet agglomerate under the addition of dry material. Plants are often designed so that both production methods can be used. Build-up agglomeration runs in a batch process, with a batch time of e.g. five minutes (Figure above). The raw materials (of which there can be more than 20 in some cases) are loaded in batches into the mixer, and fluid is added after brief dry mixing. The granulating fluid can be water or a salt solution, in which case there is no need to grind the salt to granulating fineness. Likewise, it is also possible to add process slurries or filter cakes from wet grinding or recycling processes. These additions are made in an area in which the material is immediately drawn in and distributed throughout the material being mixed within a matter of seconds. If the granulate is also to be coated, then solids are added at the end of the granulation process. If the recipe demands the input of superheated steam, this is also no problem since any risk of localized overheating is reliably ruled out by the immediate admixing process.

2. Organic fertilizers and soil improvers

Disk pelletizers are the perfect choice here to obtain the classic grain spectrum of 2-5 mm. The background to this is the low green strength of the pellets. In the case of inorganic fertilizers, capillary forces and salts provide sufficient green strength in the mixer during production, but these factors are absent in the case of organic fertilizers. In the disk pelletizer, the process of rolling the pellets with low input of forces is enough to achieve sufficient grain growth through material exchange. Typical examples include organic filtration residues from the production of foods, drink/tobacco products, and animal feed, or fermentation sludge and digested sludge.

Summary

Disk pelletizers and pelletizing drums are used for applications where granules with a narrow grain spectrum and/or high demands in terms of roundness are to be produced. In addition, disk pelletizers are also recommended for the production of large pellets, which are often used in metallurgical processes in sizes of up to approx. 30 mm. Mixers are often incorporated upstream in order to condition the pellet feed. Major applications for this solution include the processing of ores. A further application of disk pelletizers and pelletizing drums is during the production of organic fertilizers.

Compulsory mixers with a rotating pan are recommended for the production of granules up to around 8 mm. Example applications include the production of NPK fertilizers, tiles, molecular sieves, oxide ceramics, dental ceramics, grinding tools and proppants. New applications have been added recently, such as the granulating of ashes into synthetic sand that is suitable for use as a construction material.