Biomontan tests acrylamide-free flocculant for sand and gravel washing

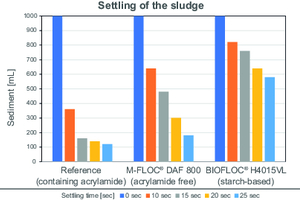

Water from washing sand and gravel is usually treated with the addition of polymer flocculants, cleaned to remove any solids and reused. State of the art are flocculants that contain a small amount of acrylamide. In a laboratory test, acrylamide-free M-FLOC® DAF 800 from Biomontan demonstrates stable flocculation, with low turbidity and rapid sedimentation and, compared with starch-based flocculants, impresses with greatly improved cleaning efficiency.

In process water treatment, the fine particles are removed by sedimentation in large settling tanks, clarifiers or lamella separators with subsequent dewatering. The addition of polymeric flocculants...