Development of a new process to produce gypsum products from potash mining

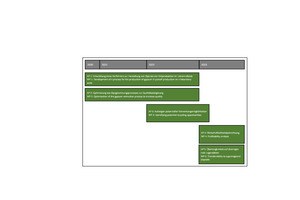

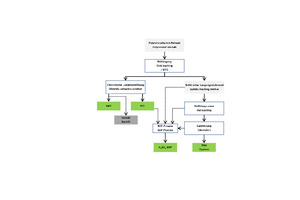

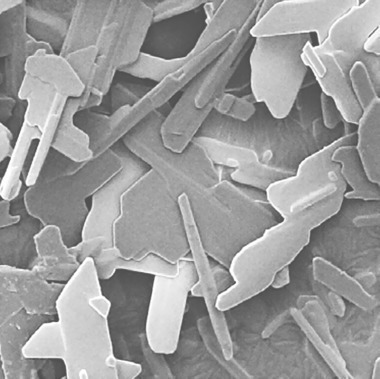

The extraction of calcium sulphate products from potash mining can be one possibility to produce gypsum from a secondary source of raw materials in future. Work is currently underway on the necessary basis for this within the framework of the PolyGips research project (funded by Germany’s Federal Ministry of Education and Research [BMBF] in the scope of the funding programme “WIR! – Wandel durch Innovation in der Region” – Change with Innovation in the Region). The development of a process with subsequent laboratory testing of the specimen material is a central element in the research project. Crucial is the quality of the gypsum produced as this influences its further utilization and the feasibility study for the developed process.

1 Introduction

With the phase-out of coal-fired power generation and the subsequent loss of gypsum from flue gas desulphurization plants (FGD gypsum) in Germany, the gypsum-processing industry faces a huge challenge. The reason for this is that up to 55 % of German gypsum demand has been met with FGD gypsum in the past [1]. For the opening “gypsum gap”, alternatives must be found to satisfy the existing raw material demand, so as not to fall back exclusively on an increased use of natural gypsum. Even if the general shortage of gypsum as a resource can be alleviated in the short term on...