Eliminating material flow problems with bulk goods

The pneumatic knocker was developed over 50 years ago by company founder Erwin Lüer. Even today, singold’s pneumatic knockers remain the most powerful on the market. More importantly, they only knock when actually needed. This reduces strain on weld seams, which would otherwise fatigue under constant vibrations. A pneumatic knocker that is used as required helps protect containers, minimises compressed air consumption and improves workplace noise levels.

Selecting the right knocker is straightforward, as only a few key factors need to be considered. After all, on-site users know their systems best. Practical experience usually makes it easy to choose the most suitable pneumatic knocker. For those seeking guidance – such as when implementing new systems – singold gerätetechnik gmbh provides expert support, offering advice as equals and always valuing the user’s practical experience.

The singold configurator, available on the company’s website, identifies the ideal pneumatic knocker in just three steps and creates an automated enquiry. What temperatures will the knocker be exposed to? What is the diameter and sheet thickness of the silo? By answering these questions, the configurator ensures the right knocker is selected for each application. Are there any special requirements due to aggressive dust? Will the knocker be used in hygiene-sensitive environments such as food production? All these factors are relevant when selecting the right knocker and can be easily assessed by on-site users. The optimal design and number of knockers can then be intuitively determined using a clear, interactive diagram.

Design and operation of the pneumatic knocker type K

Selecting the right pneumatic knocker is simple, and so is understanding how it works. The singold magnetic system knocker achieves high impact energy by spontaneously releasing stored compressed air energy.

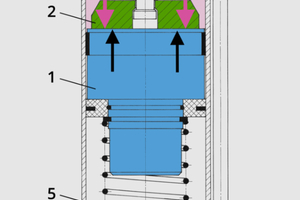

Fig. 1 illustrates a cross-section of the knocker:

1. The impact piston, designed as a permanent magnet, adheres to the anchor plate in the basic position due to magnetic force.

2. Compressed air is supplied via the connecting thread.

3. As pressure builds, it overcomes the magnetic force, causing the piston to suddenly detach.

4. The piston accelerates rapidly and hits the striker bolt at 6 – 7 m/s, transferring the impact energy directly to the silo wall via the welding plate.

5. After venting, the spring resets the piston to its initial position.

The pneumatic knocker is highly effective for bulk materials experiencing flow disturbances such as bridging, shaft formation and residue buildup – especially when high-speed or sinusoidal vibrators fail to deliver results. Unlike vibrators, the knocker generates a purely elastic impact without introducing imbalance forces or continuous vibrations. This ensures powerful yet controlled material activation while minimising wear on the container.

The knocker is typically electrically controlled via a solenoid valve. For special applications, such as container changes, slowly rotating drums or hot walls, singold gerätetechnik gmbh offers the distance knocker, which uses an extended piston rod to transfer impact across a gap.

By combining practical experience with ingenious engineering, singold delivers effective, user-friendly solutions – ensuring that bulk materials flow freely again.

Author:

Dr. Nadja Hadek, Copywriter