Intelligent safety line coupling now wireless

1 Crushing plants can now also be safely connected per radio thanks to the Kleemann “Wireless line coupling”

1 Crushing plants can now also be safely connected per radio thanks to the Kleemann “Wireless line coupling”

© Wirtgen

Optimised material flow

The crushing process of the Kleemann crushing plants is optimised automatically by the innovative feed control CFS (Continuous Feed System) so that material is always conveyed with maximum efficiency through the machines. At the same time, the filling level of the plant’s crushing chamber is monitored. When the filling level reaches a height that can be defined in advance, the material feed of the machine is adjusted. This system forms the perfect basis for the line coupling of an interlinked plant train. The optionally available probes at the crusher discharge conveyor and/or fine grain conveyor of the upstream machine monitor the filling level of the feeding unit of the respective upstream machine. When the filling level also reaches a defined height here, the output of the upstream plant is temporarily reduced.

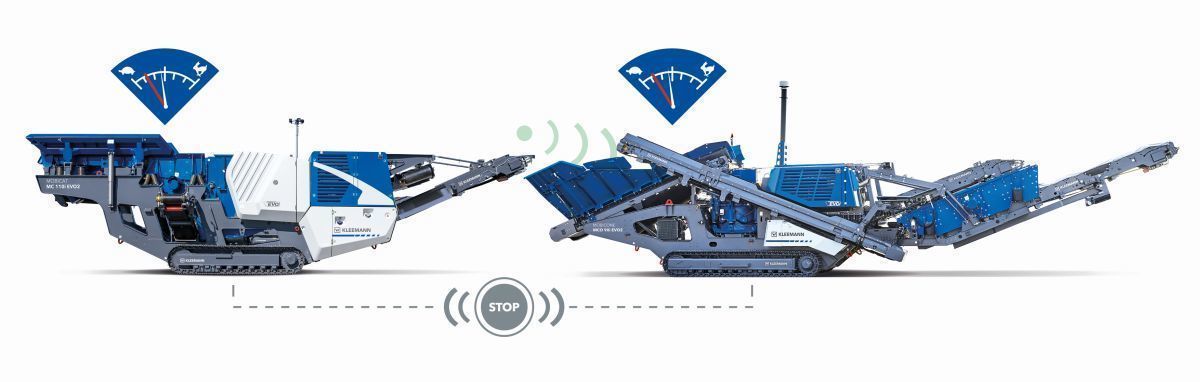

2 Jaw crusher MOBICAT MC 110i EVO2 and cone crusher MOBICONE MCO 90i EVO2 coupled intelligently

2 Jaw crusher MOBICAT MC 110i EVO2 and cone crusher MOBICONE MCO 90i EVO2 coupled intelligently

© Wirtgen

Safely connected via radio by means of “Wireless line coupling”

If an emergency stop button is pressed on the plant train in the event of an emergency, all machines are safely stopped. This is guaranteed by the safety coupling of the plants. For this purpose, apart from the cable connection new technology is also available: coupling via a radio system. The “Wireless line coupling” is easier to handle and makes the typical workday of the operator easier. Complex cable routing is no longer necessary and easy conversion of the plants is also possible.

Thanks to the intelligent line coupling from Kleemann, overload situations and damage are prevented. All of this combined results in a high availability and output with low wear. The new technology “Wireless line coupling” is currently available as an option for the jaw crushers MOBICAT MC 110(i) EVO2 and MC 120(i) PRO, cone crushers MOBICONE MCO 90(i) EVO2 and MCO 110(i) PRO and the impact crushers MOBIREX MR 110(i) EVO2, MR 130(i) EVO2 and MR 130(i) PRO.