Automatic grinding bowl clamping, imbalance control and comminution down to the nano range

12.07.2023FRITSCH’s premium line Planetary Ball Mills PULVERISETTE 5 and 7 can grind, alloy, mix and homogenize reliably at bowl speeds of up to 2200 rpm. It’s possible to effortlessly grind hard, medium, soft, brittle and moist samples down to a final fineness of < 100 nm in a very short time. Sample quantities of 1 to 60 ml (PULVERISETTE 7) or 15 to 450 ml (PULVERISETTE 5) can be processed simultaneously at the two grinding stations.

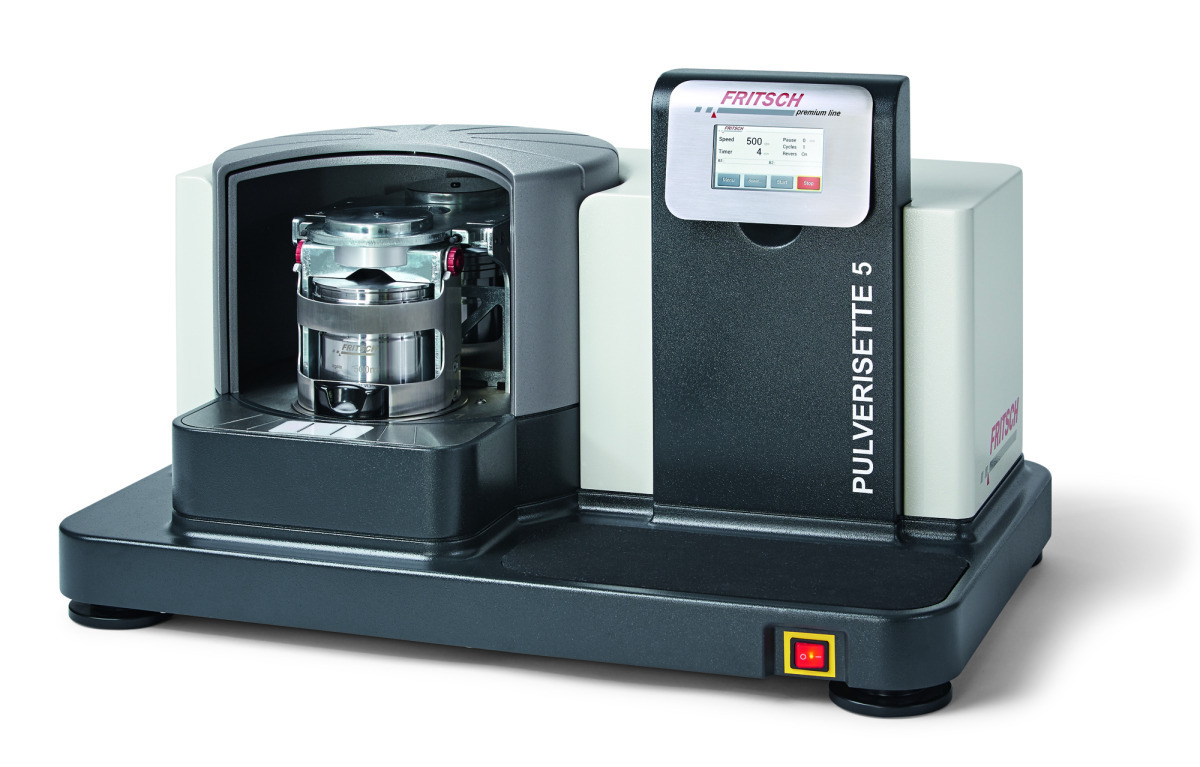

Planetary Mill PULVERISETTE 5 premium line: high-performance grinding down to the nano range for large quantities in up to 4 grinding bowls of 125 ml to 500 ml volume

Planetary Mill PULVERISETTE 5 premium line: high-performance grinding down to the nano range for large quantities in up to 4 grinding bowls of 125 ml to 500 ml volume

© Fritsch

The Top 3 advantages of the planetary mills premium line

- Faster: final fineness down to <100 nm in 3 minutes due to high bowl speed of up to 2200 rpm

- Safer: automatic grinding bowl clamping – user-independent, reproducible and safe

- User-friendly: easy grinding bowl insertion and blockage of the start if operating state is impermissible

Planetary Micro Mill PULVERISETTE 7 premium line: nano grinding for small quantities in 2 grinding bowls of 20 ml to 80 ml volume

Planetary Micro Mill PULVERISETTE 7 premium line: nano grinding for small quantities in 2 grinding bowls of 20 ml to 80 ml volume

© Fritsch

For both wet and dry grinding, the process is easy to start due to the guided positioning of the grinding bowl and the automatic bowl detection for the correct speed. Due to the automatic grinding bowl clamping, it’s possible to grind with the reassuring feeling that the grinding bowl is always correctly mounted and clamped, without the need for any cumbersome screwing. Grinding has never been as safe.

With the optional EASY GTM system, gas pressure and temperature can be measured directly in the grinding bowl during the grinding process.

Customers can send a sample of their most difficult grinding material – FRITSCH will conduct an individual sample grinding.