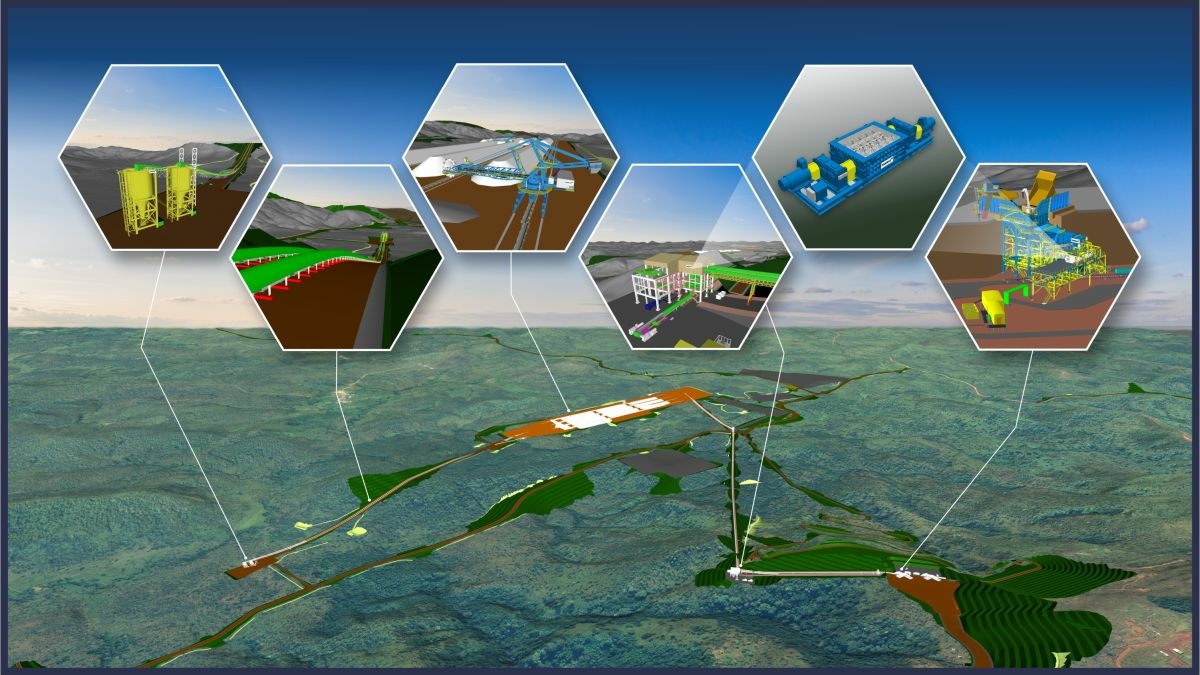

FLSmidth receives order for In-Pit Crushing & Conveying (IPCC) equipment

19.01.2022FLSmidth has been chosen to supply In-Pit Crushing & Conveying (IPCC) equipment for the upstream section of Polyus’ Blagodatnoye gold mine. The order follows October’s announcement that FLSmidth would supply a large package of process equipment for the expansion of the same mine.

© FLSmidth

This new order for IPCC equipment comprises a semi-mobile crushing station with the TSUV Gyratory Crusher, an apron feeder and a 1.6-km-long overland conveyor, which will transport the material to the concentrator. The equipment has been customised for the project and includes a modular design with opposite truck ramps and enlarged discharge hopper. Components were selected due to their ability to perform in harsh conditions where temperatures reach - 40 °C.

© FLSmidth

This new order for IPCC equipment comprises a semi-mobile crushing station with the TSUV Gyratory Crusher, an apron feeder and a 1.6-km-long overland conveyor, which will transport the material to the concentrator. The equipment has been customised for the project and includes a modular design with opposite truck ramps and enlarged discharge hopper. Components were selected due to their ability to perform in harsh conditions where temperatures reach - 40 °C.

“We are happy to confirm this significant IPCC order, which follows our recent agreement with Polyus to provide the mineral processing equipment at Blagodatnoye,” says Alexey Kutilin, VP Head of Capital Sales ENAR, Mining. “It underlines our strength as a full flowsheet provider of productivity-enhancing solutions for the mining industry.”

Branco Lalik, Global Director for Mining Systems at FLSmidth, adds: “This large IPCC order is a clear show of confidence for our continuous mining technologies and for our market-leading TSUV Gyratory Crusher. In fact, the new steel structure-based, crushing station, with apron feeder discharge, is just the latest crushing station order in hard rock applications for FLSmidth, proving our successful strategy for flexible, customised design that meets each customer’s unique requirements.”

The MissionZero Mine: IPCC systems can be a viable replacement for truck fleets that run on fossil fuels. The positive environmental impact of continuous material transportation on belt conveyors powered with electrical drives can be enormous, with studies showing significant GHG emission reductions. IPCC technology allows for reducing truck haulage in mines by moving the primary crusher from the processing plant closer to the mine for the crushing and conveying of Run-of-Mine (ROM) material.