Metso Outotec introduced a comprehensive Tailings Management Solutions portfolio

02.06.2022Metso Outotec introduced its comprehensive Tailings Management Solutions offering for the sustainable management of mine tailings. The offering unites the company’s frontrunning products with decades of process expertise and covers tailings thickening and dewatering as well as handling through conveying and dry stacking. In addition, Metso Outotec offers a frontrunning portfolio of solutions for the treatment of water produced during dewatering, enabling closed water loops while managing the level of impurities within the recycled water.

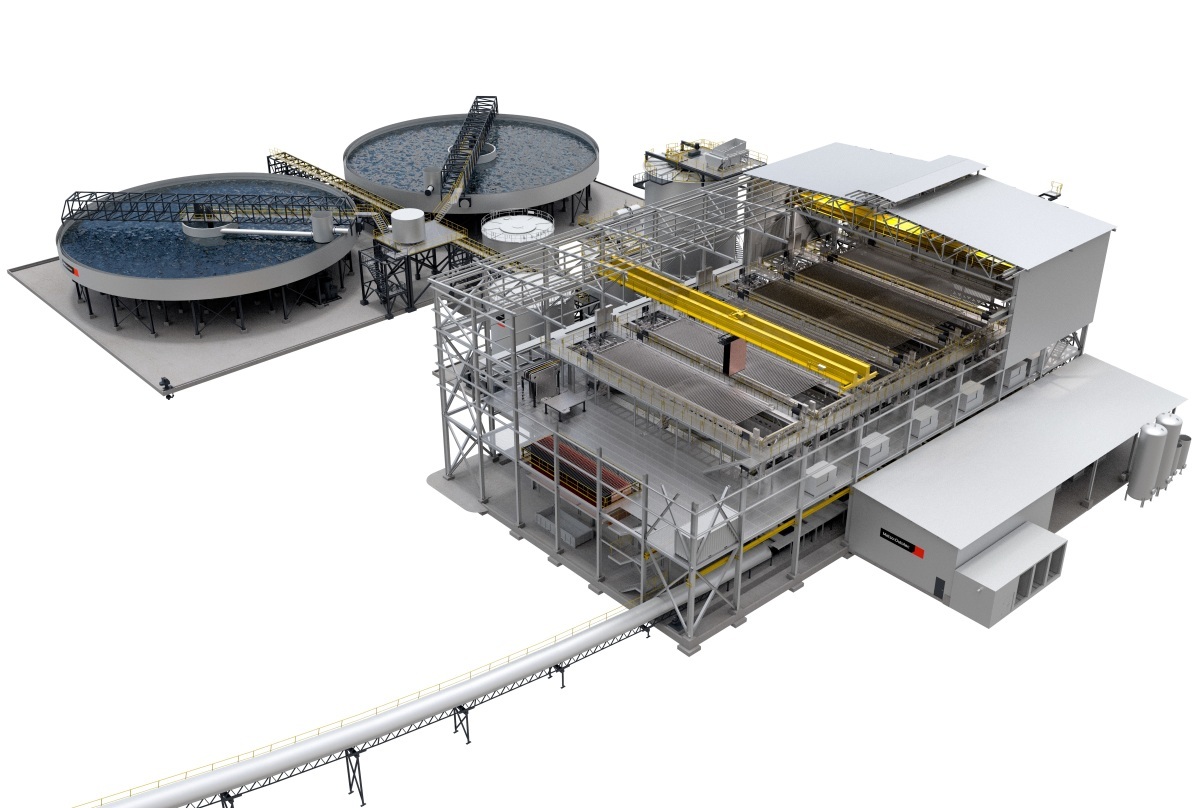

Metso Outotec tailings plant

Metso Outotec tailings plant

© Metso Outotec

“The rising demand for sustainably mined materials and stricter environmental legislation are pushing the need for more advanced technology for safe processing and storing of the tailings. Water resource efficiency is also becoming more and more important. These factors, combined with the need to capture the full value of ore, for example, by reprocessing the tailings to extract the remaining valuable minerals, lead to a continuously increasing need for sophisticated tailings management solutions,” explains Dr. Piia Suvio, Director, Tailings and Water, Metso Outotec.

“With our extensive process expertise, we can offer cutting edge technology solutions for any tailings management need to reduce water use, environmental impact, risks, and costs. Together with our customers, we can reshape the future of tailings and drive responsible management practices that help the business and society to prosper,” says Suvio.

Full scope of solutions for optimal results

Metso Outotec has been involved in the development of tailings management solutions and equipment for over 50 years. Today, a lot of emphasis is put on the design stage, which includes, for example, test work and studies supported by process simulations carried out with the recently launched Metso Outotec GeminexTM digital twin, allowing accurate plant design and sizing.

Metso Outotec’s Tailings Management Solutions consist of a wide range of Planet Positive equipment and feature performance and capacity guarantees:

· Thickening plant units are based on Metso Outotec IPS, HRT, HCT and PT technologies. The Reactorwell™ feed system and Vane FeedwellTM provide enhanced mixing, dilution, and retention of the feed, maximizing flocculant adsorption and aggregate growth. The advanced Metso Outotec control systems, such as the thickener optimizer, help improve the overall performance of the thickening plant unit.

· Filtration plant units are based on proven FFP or FP-S filtration technology. The Metso Outotec filtration plant unit is specifically designed for high-volume tailings processing, leading to savings in operational and maintenance costs.

· The company’s extensive conveying and stacking portfolio consists of robust components and is built to last and perform under even the toughest conditions.

· Metso Outotec process water recycling plants enable the recovery and reuse of water within the production process with enhanced metal recovery within the flotation circuit.

Metso Outotec supports its tailings management portfolio with a full range of parts, inspections, process optimization and Life Cycle Services.